US Army Uniform Profile

Enlisted Men's Wool Dismounted Uniform for Garrison

(1940‐42)

Point or touch each image for caption.

Right side view of the restyled olive‐drab field cap of 1940 (Caps, Field; Specification dated 11 October 1940). This cap featured rounded peaks, a bellows crown, and a turned‐up curtain that crossed in the front. It replaced the previous cap which had pointed peaks. The fabric was an 18‐ounce serge wool in olive drab shade 33. This cap was used for both field and garrison wear and began replacing the campaign hat and service cap as a general issue item in the fall of 1940. By mid‐1942, components of the wool service uniform were reclassified as garrison clothing resulting in the nomenclature for the field cap being changed to the more familiar garrison cap.

Right side view of the restyled olive‐drab field cap of 1940 (Caps, Field; Specification dated 11 October 1940). This cap featured rounded peaks, a bellows crown, and a turned‐up curtain that crossed in the front. It replaced the previous cap which had pointed peaks. The fabric was an 18‐ounce serge wool in olive drab shade 33. This cap was used for both field and garrison wear and began replacing the campaign hat and service cap as a general issue item in the fall of 1940. By mid‐1942, components of the wool service uniform were reclassified as garrison clothing resulting in the nomenclature for the field cap being changed to the more familiar garrison cap.

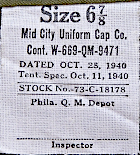

Contractor's label for the field cap shown to the left and right. Labels were attached to the sweat band seam at the right rear of the cap. Contract 9471 was issued to the Mid‐City Uniform Cap Co. of Chicago on 28 October 1940. Though there was no specification number assigned to this cap, both the cotton and wool field caps would be unified under specification QMC 8‐114A in early 1941.

Contractor's label for the field cap shown to the left and right. Labels were attached to the sweat band seam at the right rear of the cap. Contract 9471 was issued to the Mid‐City Uniform Cap Co. of Chicago on 28 October 1940. Though there was no specification number assigned to this cap, both the cotton and wool field caps would be unified under specification QMC 8‐114A in early 1941.

Left side view of the olive drab field cap. Army regulations allowed for colored branch of service corded braid to be worn on the edge of the cap. In this case, the scarlet color represents both the field artillery and costal artillery branches. Additionally, regulations allowed for the wearing of distinguished unit insignia at the front of the cap on the left side. Attached is the crest representing the 124th Field Artillery Regiment attached to the 33rd Infantry Division.

Left side view of the olive drab field cap. Army regulations allowed for colored branch of service corded braid to be worn on the edge of the cap. In this case, the scarlet color represents both the field artillery and costal artillery branches. Additionally, regulations allowed for the wearing of distinguished unit insignia at the front of the cap on the left side. Attached is the crest representing the 124th Field Artillery Regiment attached to the 33rd Infantry Division.

Contractor's label printed inside the service cap shown to the left. The label was stamped in ink on the reverse side of the leather sweatband. Contract number 8266 was awarded to Mid‐City Uniform cap company of Chicago on 19 July 1940 for $74,000. The contract was completed in November of that year. Mid‐City made millions of dollars in headgear for the Army and Marines during the World War 2 years.

Contractor's label printed inside the service cap shown to the left. The label was stamped in ink on the reverse side of the leather sweatband. Contract number 8266 was awarded to Mid‐City Uniform cap company of Chicago on 19 July 1940 for $74,000. The contract was completed in November of that year. Mid‐City made millions of dollars in headgear for the Army and Marines during the World War 2 years.

Olive‐drab serge service cap (Specification QMC 8‐5E, 12 December 1934). The service cap featured a leather visor, sweatband, and chinstrap, as well as a wicker frame. A standard component of the enlisted man's wool service uniform at the beginning of 1940, the service cap was gradually replaced by the field cap shown above. Though officially discontinued, service caps continued to be made and sold commercially throughout the war years for soldiers who wore them while on leave.

Olive‐drab serge service cap (Specification QMC 8‐5E, 12 December 1934). The service cap featured a leather visor, sweatband, and chinstrap, as well as a wicker frame. A standard component of the enlisted man's wool service uniform at the beginning of 1940, the service cap was gradually replaced by the field cap shown above. Though officially discontinued, service caps continued to be made and sold commercially throughout the war years for soldiers who wore them while on leave.

Enlisted man's leather belt worn around the waist of the wool service coat shown below. Made in Army russet shade, the belt was 1¾‐inches in width and was fastened with a brass center bar buckle. Shown here is a new type of belt that appeared in 1939 featuring a removeable buckle held in place by three pressure snaps. Also, for the first time, it had a keeper for the loop. To conserve critical materials, the leather belt was withdrawn as a standard issue item in March 1941. Thereafter, issue was only authorized for specialized purposes. Like the service cap shown to the right, the leather belt was a popular item and continued to be worn by soldiers who purchased commercial variants from retail outlets and post exchanges.

Enlisted man's leather belt worn around the waist of the wool service coat shown below. Made in Army russet shade, the belt was 1¾‐inches in width and was fastened with a brass center bar buckle. Shown here is a new type of belt that appeared in 1939 featuring a removeable buckle held in place by three pressure snaps. Also, for the first time, it had a keeper for the loop. To conserve critical materials, the leather belt was withdrawn as a standard issue item in March 1941. Thereafter, issue was only authorized for specialized purposes. Like the service cap shown to the right, the leather belt was a popular item and continued to be worn by soldiers who purchased commercial variants from retail outlets and post exchanges.

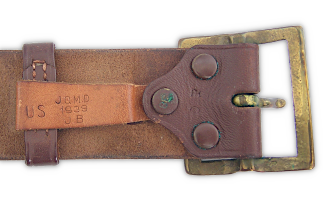

Underside view of the buckle area of the enlisted man's leather belt shown above. Visible are the three pressure snaps used to hold the buckle and loop keeper in place. The date of manufacture, in this case 1939, was pressed into the keeper along with the initials of the purchasing depot and inspector. The size was marked on the middle snap.

Underside view of the buckle area of the enlisted man's leather belt shown above. Visible are the three pressure snaps used to hold the buckle and loop keeper in place. The date of manufacture, in this case 1939, was pressed into the keeper along with the initials of the purchasing depot and inspector. The size was marked on the middle snap.

Close‐up view of the enlisted man's gilt service cap ornament worn on the cap shown to the left. The badge was affixed to the front of the cap by way of a threaded post and nut which passed through the cover and riser. Army regulations of 1941 specified that the coat of arms of the United States be a separate piece and be superimposed on a disk 1½‐inches in diameter. World War 2 era cap badges were composed of a variety of materials including brass, gold washed metal alloys, and plastic. Some economy versions were stamped or cast in one piece. The device on the badge featured here shows a distinct lack of detail indicating it is cast in one piece.

Close‐up view of the enlisted man's gilt service cap ornament worn on the cap shown to the left. The badge was affixed to the front of the cap by way of a threaded post and nut which passed through the cover and riser. Army regulations of 1941 specified that the coat of arms of the United States be a separate piece and be superimposed on a disk 1½‐inches in diameter. World War 2 era cap badges were composed of a variety of materials including brass, gold washed metal alloys, and plastic. Some economy versions were stamped or cast in one piece. The device on the badge featured here shows a distinct lack of detail indicating it is cast in one piece.

Rear view of the enlisted man's wool service coat. Visible are the shoulder pleats, cloth half belt, hooks to support the leather belt, and rear skirt vent. In March 1941, the belt hooks were discontinued after the leather belt was withdrawn as a standard issue item. However, the leather belt remained a popular item for wear on leave and could be purchased commercially throughout the war years. Because of this situation, belt hooks were often permanently removed from older coats or added to newer ones depending on whether the soldier desired to wear the belt.

Rear view of the enlisted man's wool service coat. Visible are the shoulder pleats, cloth half belt, hooks to support the leather belt, and rear skirt vent. In March 1941, the belt hooks were discontinued after the leather belt was withdrawn as a standard issue item. However, the leather belt remained a popular item for wear on leave and could be purchased commercially throughout the war years. Because of this situation, belt hooks were often permanently removed from older coats or added to newer ones depending on whether the soldier desired to wear the belt.

Thirty‐Third Infantry Division shoulder sleeve insignia. Army regulations of 1941 allowed for the wearing of cloth shoulder sleeve insignia on the left sleeve, ½‐inch from the top of the shoulder. Shoulder sleeve insignia could be made out of a variety of materials including wool, felt, embroidery, and bullion threads. Fully embroidered insignia became the dominant type beginning in 1942. The example shown here is fully embroidered.

Thirty‐Third Infantry Division shoulder sleeve insignia. Army regulations of 1941 allowed for the wearing of cloth shoulder sleeve insignia on the left sleeve, ½‐inch from the top of the shoulder. Shoulder sleeve insignia could be made out of a variety of materials including wool, felt, embroidery, and bullion threads. Fully embroidered insignia became the dominant type beginning in 1942. The example shown here is fully embroidered.

Front view the enlisted man's wool service coat (Specification QMC 8‐31D, 7 February 1940). The service coat was used for both garrison and field wear. In 1939, the coat added a pleated back and expanding lower pockets to make it more useful as a field garment. The outer fabric was 18‐ounce, olive‐drab shade 33, serge wool. After the adoption of a standard issue field jacket in 1941, the service coat was relegated to garrison wear, and in July 1942 the pleated back and expanding lower pockets were eliminated from the design.

Front view the enlisted man's wool service coat (Specification QMC 8‐31D, 7 February 1940). The service coat was used for both garrison and field wear. In 1939, the coat added a pleated back and expanding lower pockets to make it more useful as a field garment. The outer fabric was 18‐ounce, olive‐drab shade 33, serge wool. After the adoption of a standard issue field jacket in 1941, the service coat was relegated to garrison wear, and in July 1942 the pleated back and expanding lower pockets were eliminated from the design.

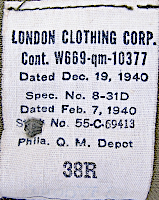

Contractor's label for the enlisted man's wool service coat shown below. The label was located inside the lower right pocket where the button is attached. Contract 10377 was issued to the London Clothing Corp. of North Abington, MA on 19 December 1940 for $61,000. The contract was completed in October 1941.

Contractor's label for the enlisted man's wool service coat shown below. The label was located inside the lower right pocket where the button is attached. Contract 10377 was issued to the London Clothing Corp. of North Abington, MA on 19 December 1940 for $61,000. The contract was completed in October 1941.

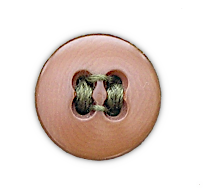

Close‐up view of one of the gilt buttons used on the service coat shown below. The coat had a total of 10 buttons: four 36‐ligne (9/10‐inch) for the front opening, one 25‐ligne (⅝‐inch) for each of the four pockets, and one 25‐ligne for each of the two shoulder loops. Army regulations called for buttons to be gold colored metal, with a raised rim, and the Coat of Arms of the United States to be displayed in clear relief against a horizontally lined background. Damage in the form of bent stems and crushed domes often occurred to these buttons when the coat was pressed during dry cleaning operations.

Close‐up view of one of the gilt buttons used on the service coat shown below. The coat had a total of 10 buttons: four 36‐ligne (9/10‐inch) for the front opening, one 25‐ligne (⅝‐inch) for each of the four pockets, and one 25‐ligne for each of the two shoulder loops. Army regulations called for buttons to be gold colored metal, with a raised rim, and the Coat of Arms of the United States to be displayed in clear relief against a horizontally lined background. Damage in the form of bent stems and crushed domes often occurred to these buttons when the coat was pressed during dry cleaning operations.

Close‐up view of the left collar insignia for the enlisted man's wool service coat shown below. Army regulations of 1941 stipulated a 1‐inch diameter disk with the insignia of arm, service, or bureau superimposed on the disk. In this case, crossed cannons indicate the field artillery branch of service. The disk was attached to the collar via a screw post and nut.

Close‐up view of the left collar insignia for the enlisted man's wool service coat shown below. Army regulations of 1941 stipulated a 1‐inch diameter disk with the insignia of arm, service, or bureau superimposed on the disk. In this case, crossed cannons indicate the field artillery branch of service. The disk was attached to the collar via a screw post and nut.

Close‐up view of the distinctive unit insignia of the 124th Field Artillery Regiment worn on the lapels of the service coat shown below and the left front of the field cap shown above. Designs for distinctive insignia had to be approved by the Adjutant General before they could be worn. Distinctive insignia could represent regiments, separate battalions, or separate companies. In this case, the 124th Field Artillery was a regiment of the 33rd Infantry Division during 1941‐42. Heraldic in design, these insignia were usually made up in enamel and were attached to the lapel by a screw post and nut.

Close‐up view of the distinctive unit insignia of the 124th Field Artillery Regiment worn on the lapels of the service coat shown below and the left front of the field cap shown above. Designs for distinctive insignia had to be approved by the Adjutant General before they could be worn. Distinctive insignia could represent regiments, separate battalions, or separate companies. In this case, the 124th Field Artillery was a regiment of the 33rd Infantry Division during 1941‐42. Heraldic in design, these insignia were usually made up in enamel and were attached to the lapel by a screw post and nut.

title="Close‐up view of the right collar insignia for the enlisted man's wool service coat shown below. Army regulations of 1941 stipulated a 1‐inch diameter disk with the "U.S." being a separate piece superimposed on the disk. The disk was attached to the collar via a screw post and nut. Non‐federalized units usually had their state abbreviation superimposed on the "U.S.". Occasionally, regiment numbers were displayed below the "U.S.".

title="Close‐up view of the right collar insignia for the enlisted man's wool service coat shown below. Army regulations of 1941 stipulated a 1‐inch diameter disk with the "U.S." being a separate piece superimposed on the disk. The disk was attached to the collar via a screw post and nut. Non‐federalized units usually had their state abbreviation superimposed on the "U.S.". Occasionally, regiment numbers were displayed below the "U.S.".

Front view of the enlisted man's wool trousers (Specification QMC 8‐83B, 9 November 1937). Wool trousers were full length with a button fly, seven belt loops, an integral waistband, two rear pockets, two hip pockets, and a front watch pocket on the right side. Three classes of trousers were produced: Class A, 18‐ounce serge wool in olive‐drab 32 "light shade" ; Class B, 18‐ounce elastique in olive‐drab 32 "light shade" ; and Class C, 20‐ounce suiting in olive‐drab shade 33. Shown here are Class A trousers, which were produced in far greater numbers than the other classes.

Front view of the enlisted man's wool trousers (Specification QMC 8‐83B, 9 November 1937). Wool trousers were full length with a button fly, seven belt loops, an integral waistband, two rear pockets, two hip pockets, and a front watch pocket on the right side. Three classes of trousers were produced: Class A, 18‐ounce serge wool in olive‐drab 32 "light shade" ; Class B, 18‐ounce elastique in olive‐drab 32 "light shade" ; and Class C, 20‐ounce suiting in olive‐drab shade 33. Shown here are Class A trousers, which were produced in far greater numbers than the other classes.

Rear view of the enlisted man's wool trousers showing the waist darts and double welt horizontal rear pocket openings. Also, note the fullness in the seat area. The Quartermaster modified the wool trousers on a number of occasions by widening the seat and increasing the rise to provide a more comfortable fit. World War 2 era trousers had a generous seam allowance and extra material at the bottom hem so that they could easily be tailored to fit.

Rear view of the enlisted man's wool trousers showing the waist darts and double welt horizontal rear pocket openings. Also, note the fullness in the seat area. The Quartermaster modified the wool trousers on a number of occasions by widening the seat and increasing the rise to provide a more comfortable fit. World War 2 era trousers had a generous seam allowance and extra material at the bottom hem so that they could easily be tailored to fit.

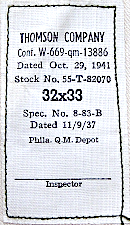

Contractor's label for the enlisted man's wool trousers shown to the left and right. The label can be found attached to the right front pocket on the side that faces the wool fabric. Contract 13886 was issued to the Thomson Company of Thomson Georgia on 29 October 1941. The Thomson factory produced large quantities of trousers for both the Army and Navy during World War 2.

Contractor's label for the enlisted man's wool trousers shown to the left and right. The label can be found attached to the right front pocket on the side that faces the wool fabric. Contract 13886 was issued to the Thomson Company of Thomson Georgia on 29 October 1941. The Thomson factory produced large quantities of trousers for both the Army and Navy during World War 2.

Close‐up view of the waistband button used on the enlisted man's wool trousers shown to the right. There were a total of five plastic buttons: one 27‐ligne waistband button and four 22‐ligne fly buttons.

Close‐up view of the waistband button used on the enlisted man's wool trousers shown to the right. There were a total of five plastic buttons: one 27‐ligne waistband button and four 22‐ligne fly buttons.

The M‐1937 waist web belt (Specification QMC 6‐105, 25 March 1938) was the standard belt worn with all enlisted men's trousers. Components consisted of an olive‐drab woven cotton belt that was 1¼‐inches wide, a frame friction buckle clamped to one end, and a small metal clip at the opposite end to prevent unraveling. Initially, specifications called for buckles to be made of blackened brass, but in the fall of 1941 the use of substitute standard materials was authorized including buckles made of oxidized steel alloy and buckle components made from stampings.

The M‐1937 waist web belt (Specification QMC 6‐105, 25 March 1938) was the standard belt worn with all enlisted men's trousers. Components consisted of an olive‐drab woven cotton belt that was 1¼‐inches wide, a frame friction buckle clamped to one end, and a small metal clip at the opposite end to prevent unraveling. Initially, specifications called for buckles to be made of blackened brass, but in the fall of 1941 the use of substitute standard materials was authorized including buckles made of oxidized steel alloy and buckle components made from stampings.

Enlisted man's flannel shirt (Shirts, Flannel, Olive‐drab, Coat-style; Specification QMC 8‐108, 2 August 1937). A dress style shirt made of wool‐cotton flannel in olive‐drab shade 31 worn with the wool service uniform in colder conditions. Both flannel and worsted shirts were cut in the same pattern and produced in tandem through 1940. By 1941, the flannel shirt became the primary shirt worn with the enlisted man's wool service uniform. The white tags attached to the front of the shirt shown above are called pin tickets (cutter's tags). They had a shade code and size printed on them to ensure garments were assembled with the correct size parts and matched in color.

Enlisted man's flannel shirt (Shirts, Flannel, Olive‐drab, Coat-style; Specification QMC 8‐108, 2 August 1937). A dress style shirt made of wool‐cotton flannel in olive‐drab shade 31 worn with the wool service uniform in colder conditions. Both flannel and worsted shirts were cut in the same pattern and produced in tandem through 1940. By 1941, the flannel shirt became the primary shirt worn with the enlisted man's wool service uniform. The white tags attached to the front of the shirt shown above are called pin tickets (cutter's tags). They had a shade code and size printed on them to ensure garments were assembled with the correct size parts and matched in color.

Enlisted man's worsted shirt (Shirts, Worsted, Olive‐drab; Specification QMC 8‐108, 2 August 1937). A dress style shirt with a standing and falling collar, front button placket, shirt style cuffs, two patch pockets with mitered corners, and a rear yoke. The fabric was worsted wool made in olive‐drab shade 31 and worn in place of the flannel shirt in warmer weather. This shirt was eliminated by the end of 1940 and replaced by the khaki cotton shirt shown below.

Enlisted man's worsted shirt (Shirts, Worsted, Olive‐drab; Specification QMC 8‐108, 2 August 1937). A dress style shirt with a standing and falling collar, front button placket, shirt style cuffs, two patch pockets with mitered corners, and a rear yoke. The fabric was worsted wool made in olive‐drab shade 31 and worn in place of the flannel shirt in warmer weather. This shirt was eliminated by the end of 1940 and replaced by the khaki cotton shirt shown below.

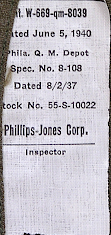

Contractor's label for the worsted shirt shown to the right. Labels were located on the inside of the right rear shirt tail. Phillips‐Jones Corp. of Barnesboro Pennsylvania was a primary shirt contractor for the Army throughout World War 2. Contract 8039 was issued on 5 June 1940. Enlisted men's worsted shirts were procured into the fall of 1940 before being discontinued. Note the difference in stock numbers when compared to the flannel shirt label to the far right.

Contractor's label for the worsted shirt shown to the right. Labels were located on the inside of the right rear shirt tail. Phillips‐Jones Corp. of Barnesboro Pennsylvania was a primary shirt contractor for the Army throughout World War 2. Contract 8039 was issued on 5 June 1940. Enlisted men's worsted shirts were procured into the fall of 1940 before being discontinued. Note the difference in stock numbers when compared to the flannel shirt label to the far right.

Close‐up view of the 10½‐ounce shirting made in olive‐drab shade 31 used to construct the worsted wool shirt shown above. The worsted shirt was made in a plain weave which allowed for better breathability in warmer conditions.

Close‐up view of the 10½‐ounce shirting made in olive‐drab shade 31 used to construct the worsted wool shirt shown above. The worsted shirt was made in a plain weave which allowed for better breathability in warmer conditions.

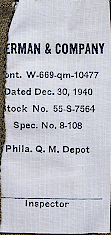

Contractor's label for the flannel shirt shown to the left. Labels were located on the inside of the right rear shirt tail. Contract 10477 was issued to Oberman & Company on 30 December 1940. Oberman & Company had multiple factories in Missouri and one in Mississippi where millions of trousers, shirts, and jackets were manufactured for the Army and Navy during the World War 2 Period. Note that the stock number for the flannel shirt differs from the number for the worsted shirt shown on the label to the far left.

Contractor's label for the flannel shirt shown to the left. Labels were located on the inside of the right rear shirt tail. Contract 10477 was issued to Oberman & Company on 30 December 1940. Oberman & Company had multiple factories in Missouri and one in Mississippi where millions of trousers, shirts, and jackets were manufactured for the Army and Navy during the World War 2 Period. Note that the stock number for the flannel shirt differs from the number for the worsted shirt shown on the label to the far left.

Close‐up view of the 10½‐ounce flannel shirting made in olive‐drab shade 31 that was used in the construction of the shirt shown above. By 1941, flannel was the primary material used to manufacture enlisted men's wool shirts.

Close‐up view of the 10½‐ounce flannel shirting made in olive‐drab shade 31 that was used in the construction of the shirt shown above. By 1941, flannel was the primary material used to manufacture enlisted men's wool shirts.

Black wool necktie (Necktie, Black, Wool, M‐1940; specification QMC 8‐119, 31 January 1941). This necktie superseded the black silk necktie of 1936. It was 45‐ inches long, made of challis, fully lined, folded into triangular ends, and was tied with a four‐in‐hand knot. When the service coat was not worn, the necktie was to be tucked into the shirt between the 2nd and 3rd buttons.

Black wool necktie (Necktie, Black, Wool, M‐1940; specification QMC 8‐119, 31 January 1941). This necktie superseded the black silk necktie of 1936. It was 45‐ inches long, made of challis, fully lined, folded into triangular ends, and was tied with a four‐in‐hand knot. When the service coat was not worn, the necktie was to be tucked into the shirt between the 2nd and 3rd buttons.

Front view of the enlisted men's 8.2‐ounce khaki cotton shirt (specification QMC 6‐241, 29 November 1938). This was the standard issue shirt worn with the cotton summer uniform. It shared similar design characteristics with the olive‐drab worsted and flannel shirts shown above. By 1941, the cotton shirt replaced the olive‐drab worsted shirt for wear with the wool uniform when the flannel shirt was not appropriate.

Front view of the enlisted men's 8.2‐ounce khaki cotton shirt (specification QMC 6‐241, 29 November 1938). This was the standard issue shirt worn with the cotton summer uniform. It shared similar design characteristics with the olive‐drab worsted and flannel shirts shown above. By 1941, the cotton shirt replaced the olive‐drab worsted shirt for wear with the wool uniform when the flannel shirt was not appropriate.

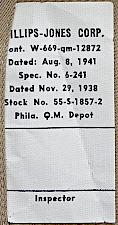

Contractor's label for the khaki cotton shirt shown to the left. Labels were located on the inside of the right rear shirt tail. Phillips‐Jones Corp. of Barnesboro Pennsylvania was a primary shirt contractor for the Army throughout World War 2. Contract 12872 was awarded on 8 August 1941 for $252,000 and completed in February 1942.

Contractor's label for the khaki cotton shirt shown to the left. Labels were located on the inside of the right rear shirt tail. Phillips‐Jones Corp. of Barnesboro Pennsylvania was a primary shirt contractor for the Army throughout World War 2. Contract 12872 was awarded on 8 August 1941 for $252,000 and completed in February 1942.

Display showing the M‐1939 wool service coat, flannel shirt, black wool necktie, and leather belt worn together. Smart, good looking, and presenting a nice mixture of traditional and modern design elements, this ensemble was, unfortunately, short lived. Conservation pressures and the development of a dedicated field jacket made some of its features unnecessary. In the spring of 1941, the belt was eliminated to conserve leather and brass. Once the leather belt was withdrawn from issue, new coats were produced without belt hooks and sometimes removed from older coats. In the summer of 1942, the coat, no longer used in the field, would lose its pleated back and bellows lower pockets, and the black necktie would be changed to khaki shade no. 5.

Display showing the M‐1939 wool service coat, flannel shirt, black wool necktie, and leather belt worn together. Smart, good looking, and presenting a nice mixture of traditional and modern design elements, this ensemble was, unfortunately, short lived. Conservation pressures and the development of a dedicated field jacket made some of its features unnecessary. In the spring of 1941, the belt was eliminated to conserve leather and brass. Once the leather belt was withdrawn from issue, new coats were produced without belt hooks and sometimes removed from older coats. In the summer of 1942, the coat, no longer used in the field, would lose its pleated back and bellows lower pockets, and the black necktie would be changed to khaki shade no. 5.

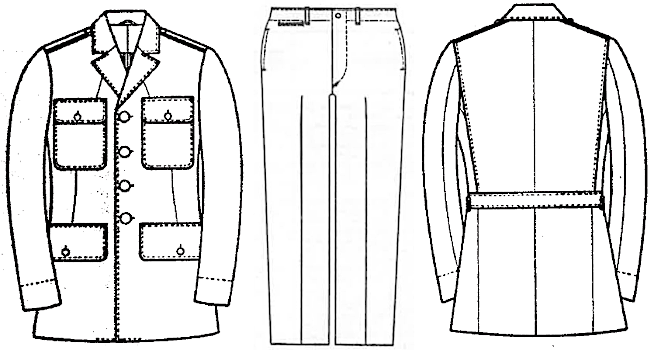

Drawings from US Army specifications depicting the front and back of the enlisted men's wool service coat (specification 8‐31D, 7 February 1940) and the front of the wool trousers (specification 8‐83B, 9 November 1937). Specification 8‐31D was procured through May 1942 and 8‐83B through January 1943.

Drawings from US Army specifications depicting the front and back of the enlisted men's wool service coat (specification 8‐31D, 7 February 1940) and the front of the wool trousers (specification 8‐83B, 9 November 1937). Specification 8‐31D was procured through May 1942 and 8‐83B through January 1943.

Close‐up view of the 18‐ounce serge wool fabric in olive‐drab shade 33 used in the construction of the enlisted man's wool service coat, service cap, and field cap. The same fabric was used in the construction of the enlisted man's wool trousers except in olive‐drab shade 32 "light shade". Note the diagonal lines evident in the weave. The term serge refers to this ribbed pattern and was used to enhance the garment's durability.

Close‐up view of the 18‐ounce serge wool fabric in olive‐drab shade 33 used in the construction of the enlisted man's wool service coat, service cap, and field cap. The same fabric was used in the construction of the enlisted man's wool trousers except in olive‐drab shade 32 "light shade". Note the diagonal lines evident in the weave. The term serge refers to this ribbed pattern and was used to enhance the garment's durability.

Close‐up views of the distinguishing features of the enlisted man's wool service coat (specification QMC 8‐31D, 7 February 1940). Left to right: One of the brass belt hooks used to support the leather belt, bellows lower pocket meant to increase carrying capacity, and pleated back that allowed the arms to move more freely without the coat riding up on the body. Leather and brass conservation initiatives and the adoption of the field jacket resulted in the removal of all of these features by the summer of 1942 when a revised model of the coat was approved for garrison wear.

Close‐up views of the distinguishing features of the enlisted man's wool service coat (specification QMC 8‐31D, 7 February 1940). Left to right: One of the brass belt hooks used to support the leather belt, bellows lower pocket meant to increase carrying capacity, and pleated back that allowed the arms to move more freely without the coat riding up on the body. Leather and brass conservation initiatives and the adoption of the field jacket resulted in the removal of all of these features by the summer of 1942 when a revised model of the coat was approved for garrison wear.

U.S. Army photograph taken on 20 June 1941 showing the enlisted man's wool dismounted uniform for garrison. The soldier wears the olive‐drab service cap, flannel shirt, black necktie, 18‐ounce serge wool coat with leather belt, 18‐ounce serge wool trousers in "light shade", and russet colored service shoes. Draped over his left arm is the M‐1938 raincoat.

U.S. Army photograph taken on 20 June 1941 showing the enlisted man's wool dismounted uniform for garrison. The soldier wears the olive‐drab service cap, flannel shirt, black necktie, 18‐ounce serge wool coat with leather belt, 18‐ounce serge wool trousers in "light shade", and russet colored service shoes. Draped over his left arm is the M‐1938 raincoat.

Close‐up view of wool corporal chevrons (fifth grade). Noncommissioned officers and first class privates wore insignia of grade on the wool uniform that included olive‐drab wool chevrons, arcs, and a lozenge on a dark blue wool background. The background was to form an edging around the entire insignia and between the chevrons. Chevrons were worn on the wool coat, overcoat, and shirt and were located on the outside of the sleeve approximately halfway between the shoulder and elbow. Separate, washable cotton chevrons were made for wear on the cotton shirt.

Close‐up view of wool corporal chevrons (fifth grade). Noncommissioned officers and first class privates wore insignia of grade on the wool uniform that included olive‐drab wool chevrons, arcs, and a lozenge on a dark blue wool background. The background was to form an edging around the entire insignia and between the chevrons. Chevrons were worn on the wool coat, overcoat, and shirt and were located on the outside of the sleeve approximately halfway between the shoulder and elbow. Separate, washable cotton chevrons were made for wear on the cotton shirt.

Close‐up view of embroidered staff sergeant chevrons (third grade). Another type of chevron worn on the wool uniform consisted of grade insignia embroidered on a dark blue wool background. As World War 2 progressed, embroidered chevrons became the most common type worn. Toward the end of 1942, a new symbol "T" was added to the insignia of grade which meant technician and was placed either under the chevrons or in the space between the chevrons and arc as appropriate for grade.

Close‐up view of embroidered staff sergeant chevrons (third grade). Another type of chevron worn on the wool uniform consisted of grade insignia embroidered on a dark blue wool background. As World War 2 progressed, embroidered chevrons became the most common type worn. Toward the end of 1942, a new symbol "T" was added to the insignia of grade which meant technician and was placed either under the chevrons or in the space between the chevrons and arc as appropriate for grade.

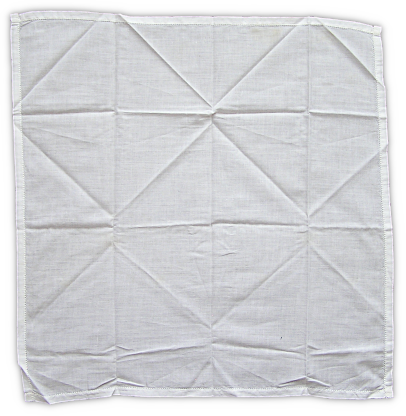

White cotton handkerchief (Handkerchief, Cotton; federal specification DDD‐H‐71, 10 November 1931). Handkerchiefs were issued with the uniform for cleanliness and sanitation. The design was composed of a single piece of white cotton fabric, 17‐inches square, and finished on all four sides with a ¼‐inch hem. The fabric was finely woven with a plain weave. Similar to gray and white undergarments, the handkerchief was changed to olive‐drab shade 3 in 1942 (Handkerchiefs, Cotton; Specification PQD 270, 28 September 1942).

White cotton handkerchief (Handkerchief, Cotton; federal specification DDD‐H‐71, 10 November 1931). Handkerchiefs were issued with the uniform for cleanliness and sanitation. The design was composed of a single piece of white cotton fabric, 17‐inches square, and finished on all four sides with a ¼‐inch hem. The fabric was finely woven with a plain weave. Similar to gray and white undergarments, the handkerchief was changed to olive‐drab shade 3 in 1942 (Handkerchiefs, Cotton; Specification PQD 270, 28 September 1942).

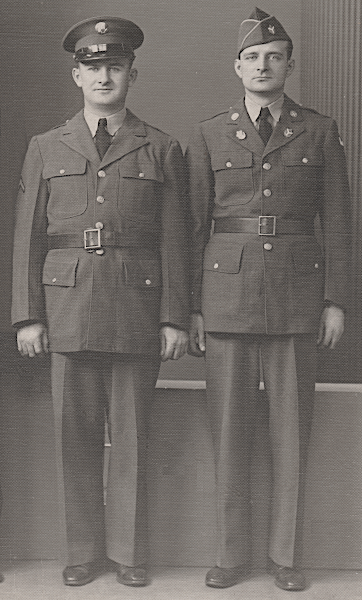

Two GIs wear the wool garrison uniform. To accentuate his uniform, the soldier on the left wears a service cap and leather belt that are both private purchase. The soldier on the right wears the olive‐drab field cap with branch of service trim and distinctive unit insignia on the left side. He also wears the distinctive insignia on the lapels of his coat. Both soldiers are wearing the khaki cotton shirt with black necktie.

Two GIs wear the wool garrison uniform. To accentuate his uniform, the soldier on the left wears a service cap and leather belt that are both private purchase. The soldier on the right wears the olive‐drab field cap with branch of service trim and distinctive unit insignia on the left side. He also wears the distinctive insignia on the lapels of his coat. Both soldiers are wearing the khaki cotton shirt with black necktie.

Enlisted man wearing the wool garrison uniform without coat. Per regulations the black necktie is tucked into the shirt between the second and third buttons when the coat is not worn. The soldier wears a specification 8‐108 wool shirt evidenced by the front button placket visible in the photo. Also, note the M‐1937 web waist belt and field cap.

Enlisted man wearing the wool garrison uniform without coat. Per regulations the black necktie is tucked into the shirt between the second and third buttons when the coat is not worn. The soldier wears a specification 8‐108 wool shirt evidenced by the front button placket visible in the photo. Also, note the M‐1937 web waist belt and field cap.

Enlisted man wearing the wool garrison uniform sans coat with khaki cotton shirt and field cap. The khaki cotton shirt was worn in lieu of the flannel shirt when warmer conditions required a lighter shirt. Originally, a worsted wool shirt with a plain weave was used for this purpose until the cotton shirt replaced it in 1941. Note the front button placket indicating the specification 6‐241 shirt as shown above.

Enlisted man wearing the wool garrison uniform sans coat with khaki cotton shirt and field cap. The khaki cotton shirt was worn in lieu of the flannel shirt when warmer conditions required a lighter shirt. Originally, a worsted wool shirt with a plain weave was used for this purpose until the cotton shirt replaced it in 1941. Note the front button placket indicating the specification 6‐241 shirt as shown above.

Soldier wearing the olive‐drab wool service uniform with overcoat. The 32‐ounce olive‐drab melton wool overcoat was worn over the wool garrison uniform when conditions warranted it. This overcoat was standard issue in regions with a winter season. In the soldier's left hand are a pair of olive‐drab woolen gloves.

Soldier wearing the olive‐drab wool service uniform with overcoat. The 32‐ounce olive‐drab melton wool overcoat was worn over the wool garrison uniform when conditions warranted it. This overcoat was standard issue in regions with a winter season. In the soldier's left hand are a pair of olive‐drab woolen gloves.

This photo shows a GI relaxing in his bunk with his wardrobe hanging overhead. From left to right are the M1917‐A1 steel helmet, gas mask carrier, raincoat, wool service coat with leather belt draped over the right shoulder, wool overcoat, flannel shirt with front button placket, and partially visible at far right is the olive‐drab field jacket and another flannel shirt. On the corner cross beam is a towel, canteen, and mess kit. On the top shelf above the man's head lay his garrison cap and a pair of work gloves.

This photo shows a GI relaxing in his bunk with his wardrobe hanging overhead. From left to right are the M1917‐A1 steel helmet, gas mask carrier, raincoat, wool service coat with leather belt draped over the right shoulder, wool overcoat, flannel shirt with front button placket, and partially visible at far right is the olive‐drab field jacket and another flannel shirt. On the corner cross beam is a towel, canteen, and mess kit. On the top shelf above the man's head lay his garrison cap and a pair of work gloves.

Contractor's label for the dismounted M‐1938 rubberized raincoat shown above. Contract 7736 was awarded to the Cable Raincoat Co. of Stoughton Massachusetts on 6 November 1939. Cable Raincoat was a primary contractor for US Army wet weather clothing during the World War 2 era.

Contractor's label for the dismounted M‐1938 rubberized raincoat shown above. Contract 7736 was awarded to the Cable Raincoat Co. of Stoughton Massachusetts on 6 November 1939. Cable Raincoat was a primary contractor for US Army wet weather clothing during the World War 2 era.

Enlisted men's dismounted M‐1938 rubberized raincoat (specification QMC 20‐104, 7 January 1939). The M‐1938 raincoat was a fairly elaborate design featuring a standing and rolling collar with throat latch, outside bellows pockets with slanted flaps, back vent, interior storm flap, and tightening straps on each sleeve. Pre‐war raincoats were made of rubberized fabric and superseded the oil treated type that dated back to the World War 1 era. In early 1942, a simplified raincoat made with synthetic resin coated fabric began replacing the rubberized type.

Enlisted men's dismounted M‐1938 rubberized raincoat (specification QMC 20‐104, 7 January 1939). The M‐1938 raincoat was a fairly elaborate design featuring a standing and rolling collar with throat latch, outside bellows pockets with slanted flaps, back vent, interior storm flap, and tightening straps on each sleeve. Pre‐war raincoats were made of rubberized fabric and superseded the oil treated type that dated back to the World War 1 era. In early 1942, a simplified raincoat made with synthetic resin coated fabric began replacing the rubberized type.

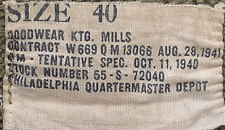

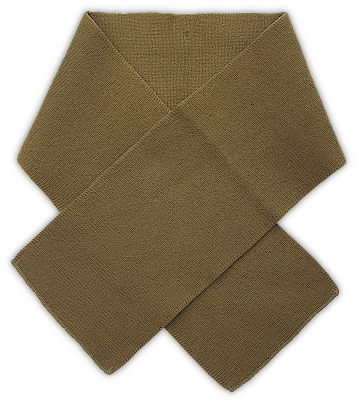

Contractor's label for the sleeveless sweater shown above. Contract 13066 was awarded to Goodwear Knitting Mills of Philadelphia, PA. on 28 August 1941. Goodwear Knitting made knitwear for both the Army and Navy throughout the World War 2 years. The revised sleeveless sweater was introduced in October 1940 along with a novel field jacket and the revised field cap shown above.

Contractor's label for the sleeveless sweater shown above. Contract 13066 was awarded to Goodwear Knitting Mills of Philadelphia, PA. on 28 August 1941. Goodwear Knitting made knitwear for both the Army and Navy throughout the World War 2 years. The revised sleeveless sweater was introduced in October 1940 along with a novel field jacket and the revised field cap shown above.

A vest‐style, medium weight, sleeveless sweater used to provide extra warmth underneath the wool service coat or field jacket (Sweaters, Sleeveless; Specification dated 11 October 1940). Made of olive‐drab worsted wool, the sleeveless sweater had a seamless body, integral waistband, and was sewn together at the shoulders. The collar and arm openings were formed using a hem and reinforced with heavy stitching. World War 2 era sweaters could be knitted using either a shaker or rib pattern.

A vest‐style, medium weight, sleeveless sweater used to provide extra warmth underneath the wool service coat or field jacket (Sweaters, Sleeveless; Specification dated 11 October 1940). Made of olive‐drab worsted wool, the sleeveless sweater had a seamless body, integral waistband, and was sewn together at the shoulders. The collar and arm openings were formed using a hem and reinforced with heavy stitching. World War 2 era sweaters could be knitted using either a shaker or rib pattern.

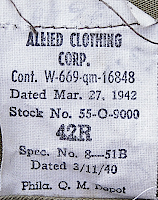

Contractor's label for the olive‐drab melton wool overcoat shown above. Allied Clothing Corp. was located in Linden New Jersey and manufactured overcoats for the Army throughout much of the war. Contract 16848 was awarded on 27 March 1942 for $367,000. The contract was completed in December 1942.

Contractor's label for the olive‐drab melton wool overcoat shown above. Allied Clothing Corp. was located in Linden New Jersey and manufactured overcoats for the Army throughout much of the war. Contract 16848 was awarded on 27 March 1942 for $367,000. The contract was completed in December 1942.

32‐ounce roll collar olive‐drab melton wool overcoat (Specification QMC 8‐51B, 11 March 1940). A standard issue item in winter areas, the overcoat was a heavyweight, double‐breasted design with convertible roll collar, notched lapels, a rear half belt, and expanding pleats in the back. Like the wool service coat, the overcoat was initially used for both field and garrison wear but was eventually reclassified as a garrison item by the end of 1942. Interestingly, shortages of warm clothing in the European Theater of Operations during the winter of 1944‐45 resulted in the wool overcoat being issued to frontline troops as an emergency stopgap measure.

32‐ounce roll collar olive‐drab melton wool overcoat (Specification QMC 8‐51B, 11 March 1940). A standard issue item in winter areas, the overcoat was a heavyweight, double‐breasted design with convertible roll collar, notched lapels, a rear half belt, and expanding pleats in the back. Like the wool service coat, the overcoat was initially used for both field and garrison wear but was eventually reclassified as a garrison item by the end of 1942. Interestingly, shortages of warm clothing in the European Theater of Operations during the winter of 1944‐45 resulted in the wool overcoat being issued to frontline troops as an emergency stopgap measure.

Olive‐drab woolen gloves (Specification QMC 8‐60A, 25 March 1937). Made of olive‐drab knitted yarn, these gloves were used in cold weather and were worn with both the garrison and field uniforms. Eventually, a leather palm was added for durability. A shortage of looms needed to produce woolen gloves in sufficient numbers to meet demand resulted in the knit type being replaced in 1942 by a cut and sewn pattern with leather palms.

Olive‐drab woolen gloves (Specification QMC 8‐60A, 25 March 1937). Made of olive‐drab knitted yarn, these gloves were used in cold weather and were worn with both the garrison and field uniforms. Eventually, a leather palm was added for durability. A shortage of looms needed to produce woolen gloves in sufficient numbers to meet demand resulted in the knit type being replaced in 1942 by a cut and sewn pattern with leather palms.

Olive‐drab knitted wool muffler. Mufflers were issued to soldiers who required extra warmth such as truck drivers and sentries. Mufflers were procured by the Army under a number of different specifications during the war, others were produced by charitable organizations such as the Red Cross for distribution to soldiers, still others were made by commercial manufacturers and sold at retail outlets and post exchanges.

Olive‐drab knitted wool muffler. Mufflers were issued to soldiers who required extra warmth such as truck drivers and sentries. Mufflers were procured by the Army under a number of different specifications during the war, others were produced by charitable organizations such as the Red Cross for distribution to soldiers, still others were made by commercial manufacturers and sold at retail outlets and post exchanges.

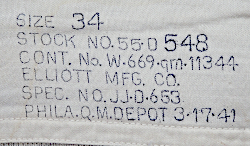

50% wool 50% cotton drawers for use in cold weather (Federal specification JJ‐D‐653, 26 October 1936). These drawers were medium weight, rib knitted, full length with attached anklets, fitted with a cotton waistband, had a three 24‐ligne button front, and a laced rear gusset. Wool drawers were made in a gray and white knit but were changed to olive‐drab in early 1943.

50% wool 50% cotton drawers for use in cold weather (Federal specification JJ‐D‐653, 26 October 1936). These drawers were medium weight, rib knitted, full length with attached anklets, fitted with a cotton waistband, had a three 24‐ligne button front, and a laced rear gusset. Wool drawers were made in a gray and white knit but were changed to olive‐drab in early 1943.

Contractor's label for the wool cotton drawers shown to the right. Elliott Mfg. Co. was located in Manchester, New Hampshire and made millions of dollars in undergarments for the Army during World War 2. Contract 11344 was awarded on 17 March 1941 for $671,000 and completed in March 1942. Contractor labels were printed on the outside of the rear waistband near the gusset.

Contractor's label for the wool cotton drawers shown to the right. Elliott Mfg. Co. was located in Manchester, New Hampshire and made millions of dollars in undergarments for the Army during World War 2. Contract 11344 was awarded on 17 March 1941 for $671,000 and completed in March 1942. Contractor labels were printed on the outside of the rear waistband near the gusset.

Tan cotton socks (federal specification JJ‐S‐566A, 26 August 1938). These socks were authorized for wear with both the cotton and wool uniforms and with a variety of shoes including standard service shoes, garrison shoes, and low quarter shoes. Tan cotton socks were primarily a dress item and therefore were not appropriate for marching and field wear.

Tan cotton socks (federal specification JJ‐S‐566A, 26 August 1938). These socks were authorized for wear with both the cotton and wool uniforms and with a variety of shoes including standard service shoes, garrison shoes, and low quarter shoes. Tan cotton socks were primarily a dress item and therefore were not appropriate for marching and field wear.

Socks wool cotton mixture (Federal specification JJ‐S‐581A, 22 August 1938). Seamless knitted socks made in a 50% Wool and 50% cotton mixture. The toes and heels were reinforced, and the cuffs were ribbed. These socks were gradually replaced by an improved design featuring cushion soles beginning in 1942.

Socks wool cotton mixture (Federal specification JJ‐S‐581A, 22 August 1938). Seamless knitted socks made in a 50% Wool and 50% cotton mixture. The toes and heels were reinforced, and the cuffs were ribbed. These socks were gradually replaced by an improved design featuring cushion soles beginning in 1942.

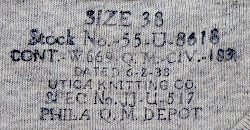

Contractor's label for the wool cotton undershirt shown to the left. The label was ink stamped on the inside nape. Contract CIV‐183 was awarded to the Utica Knitting Co. of Utica New York on 2 June 1938 for undergarments to be used by the Civilian Conservation Corps, hence the CIV prefix. After the outbreak of war, large amounts of CCC clothing made under War Department specifications were absorbed into the Army to help offset shortages. Utica was awarded millions of dollars in contracts to make undergarments for the Army, Navy, and Marines during World War 2.

Contractor's label for the wool cotton undershirt shown to the left. The label was ink stamped on the inside nape. Contract CIV‐183 was awarded to the Utica Knitting Co. of Utica New York on 2 June 1938 for undergarments to be used by the Civilian Conservation Corps, hence the CIV prefix. After the outbreak of war, large amounts of CCC clothing made under War Department specifications were absorbed into the Army to help offset shortages. Utica was awarded millions of dollars in contracts to make undergarments for the Army, Navy, and Marines during World War 2.

50% wool 50% cotton undershirt for use in cold regions (Federal Specification JJ‐U‐517, 26 October 1936). This undershirt was medium weight, rib knitted, with a high military collarette neck, and a hemmed bottom. The body was seamless with arms and wristlets being attached in separate pieces. Undergarments of this time were gray and white in color, however the Army referred to these garments as white or sometimes natural gray. The color was changed to olive‐drab in early 1943.

50% wool 50% cotton undershirt for use in cold regions (Federal Specification JJ‐U‐517, 26 October 1936). This undershirt was medium weight, rib knitted, with a high military collarette neck, and a hemmed bottom. The body was seamless with arms and wristlets being attached in separate pieces. Undergarments of this time were gray and white in color, however the Army referred to these garments as white or sometimes natural gray. The color was changed to olive‐drab in early 1943.

Garrison Shoes (specification QMC 9‐35A, October 1932). Though similar looking to standard high‐top service shoes, garrison shoes were lined with cotton and built for comfort instead of marching. They were made with calfskin uppers making them much softer and easier to break in. Tan low-quarter shoes, a restricted issue item for much of the war, began to replace garrison shoes in 1941.

Garrison Shoes (specification QMC 9‐35A, October 1932). Though similar looking to standard high‐top service shoes, garrison shoes were lined with cotton and built for comfort instead of marching. They were made with calfskin uppers making them much softer and easier to break in. Tan low-quarter shoes, a restricted issue item for much of the war, began to replace garrison shoes in 1941.

US Army service shoes (specification QMC 9‐6E, 5 March 1934). Service shoes were made in Army russet shade, constructed in a blucher pattern, had unlined cowhide uppers, leather outsoles, and stacked leather heels. The Goodyear welt method was used to attach the soles to the uppers. Rubber heels were added to the service shoe in 1940 and then in late 1941 rubber taps were added to the outsoles forward of the shank.

US Army service shoes (specification QMC 9‐6E, 5 March 1934). Service shoes were made in Army russet shade, constructed in a blucher pattern, had unlined cowhide uppers, leather outsoles, and stacked leather heels. The Goodyear welt method was used to attach the soles to the uppers. Rubber heels were added to the service shoe in 1940 and then in late 1941 rubber taps were added to the outsoles forward of the shank.

Evolution of service shoe soles 1934‐42. Left to right are specifications 9‐6E with leather sole and stacked leather heel, 9‐6F Type I with leather soles and rubber heel, and 9‐6F Type II with rubber tap and heel. Beginning in 1943, a full rubber outsole and rubber heel would be adopted.

Evolution of service shoe soles 1934‐42. Left to right are specifications 9‐6E with leather sole and stacked leather heel, 9‐6F Type I with leather soles and rubber heel, and 9‐6F Type II with rubber tap and heel. Beginning in 1943, a full rubber outsole and rubber heel would be adopted.

US Army Enlisted Men's Wool Dismounted Uniform for Garrison (1940‐42)

Background

The enlisted man's wool service uniform of 1940‐42 occupied a brief period in history where traditional and modern design elements merged to create a visually pleasing and relatively comfortable military outfit. However, because it was intended to be a dual‐purpose field and garrison uniform, over emphasis on comfort and style left it with questionable suitability for field use. Though numerous improvements in the design and function of various components of the uniform were instituted between 1937 and 1941, the uniform was, for the most part, obsolete before it was even issued. This was due to the rapid advancements in the areas of weapons and tactics used in modern warfare that were less compatible with old‐style uniforms; the prospects of global warfare requiring operations in a variety of climates; and the development of fabrics, weaves, and coatings better suited for outdoor use. On a more fundamental level, the wool service uniform would fall victim to the inevitable wartime conservation efforts and the doctrinal movement toward the development of separate clothing for field and garrison wear. Thus, by mid‐1942 the enlisted man's wool service uniform was relegated to garrison use and by mid‐1945 it was replaced altogether by a wool field jacket and trouser ensemble.

Between 1926 and 1937, the wool service uniform gradually shifted away from its traditional features emphasizing field use and moved towards those favoring comfort, modern looks, and garrison use. This trend started with the service coat which was redesigned in 1924 eliminating the traditional standing collar for a notched lapel. Additionally, the fabric was changed from a napped wool to serge wool, which had a smoother more refined look. Lastly, the lower pockets were changed from the patch type to the internally hung type.

In 1933, the pullover four‐button flannel shirt was replaced with a fully opening coat‐style model. The shirt was refined in 1937 by dropping some of its utilitarian features such as elbow pads and pencil pockets for a more dress‐like appearance. Also in 1937, it was decided to replace breeches with commercial style trousers as a standard article of uniform. The phase‐in process began with Air Force personnel and then extended to all dismounted troops in the other branches of service in 1938.

Leather goods went through changes as well. In 1934, shoes, belts, service cap visors and chinstraps were changed to a new more vibrant reddish‐brown color called Army Russett Shade. Throughout the 1920s and 30s, the shape of the visored service cap was altered to modernize its appearance. This included changes to the size and angle of the visor, as well as changes to the riser and size of the crown. Like the cap, incremental changes were applied to shoes throughout the 20s and 30s with peacetime procurement emphasizing the light garrison shoe over heavier service shoes.

With another world war looming, it was realized that Army uniforms needed further upgrading, this time in a reverse course to make them more useful in the field. Among the first of these items was the enlisted man's wool service coat which was reworked in 1939. This time, a pleated back and rear half‐belt were added, and the lower pockets were given a bellows pleat substantially increasing their capacity. In 1941, the seat and rise of the trousers were increased in size to better conform with soldier's physiques in what would eventually be the first in a series of such modifications.

In 1938, a foldable field cap (later renamed garrison cap) was authorized for wear by Air Force and mechanized troops in lieu of the visored service cap and brimmed service hat (aka campaign hat) for use inside the cramped confines of aircraft, trucks, and armored vehicles. Then in mid‐1940, for practical and conservation reasons, the field cap became the standard issue headgear worn by enlisted men across all branches of the Army.

By 1940 procurement of footwear was shifting away from light garrison shoes and toward service shoes. The durability of the service shoe was greatly improved with the addition of a rubber heel in 1940 and then a rubber outsole in late 1941. Also in 1940, an experimental low quarter shoe was introduced that would eventually replace the traditional high-top garrison shoe.

In 1939, the enlisted man's leather belt, worn with the service coat since the 1920s, was revised. The brass buckle was made removable for easier cleaning and was now held in place with three metal pressure snaps instead of being sewn on. Also, a leather keeper, held in place by one of the buckle snaps, was added onto the reverse side to prevent the loop from being lost.

At this stage, in the fall of 1940, upgrades to the wool service uniform were complete and the uniform was at its zenith. The basic outfit was comprised of an olive‐drab shade 33 service cap with russet visor and chinstrap, olive‐drab shade 33 service coat with russet belt, olive‐drab shade 31 flannel shirt, black wool necktie, olive‐drab shade 32 trousers, and russet shade service shoes. The wool service uniform of mid‐1940 offered a varied color palate, modern looks, and enough traditional styling to maintain a smart military appearance.

Not long after the new service coat started mass production, changes began to happen. A novel field jacket had been developed in 1940 and was ready to enter its final testing phase by the end of the year. This jacket, having a wind and water repellent green cotton shell and wool lining, was being considered to replace the wool service coat for field use.

While the traditional service cap with its leather visor and chinstrap was in the process of being phased out, the leather service belt was also dropped from the uniform. These leather items were considered expendable compared to the need for shoes and were eliminated from general issue as a conservation measure while mobilization was ramping up. Elimination of the leather belt resulted in the first change to the service coat with its integral belt hooks being officially dropped from the design effective 31 March 1941.

By the spring of 1941, the olive‐drab field jacket had been approved as a standard issue item and was being mass produced. The acceptance of the field jacket along with the development of numerous other field garments designed for all types of climatic conditions resulted in the wool service coat being regarded as unsuitable for field use. Thus, for this reason, and the need to conserve wool and brass, the service coat was redesigned in mid‐1942.

The new wool service coat of 1942 no longer had a pleated back or bellows lower pockets. Elimination of the pleated back saved a substantial amount of wool for other uses, and at the same time lowered production time and unit cost. Likewise, similar savings, albeit less significant, were achieved by the reduction of the lower pockets. Substitute standard buttons were also introduced with the new coat being made of gilt steel alloy rather than traditional brass. Meanwhile, development of the olive‐drab shade 32 trousers took a different approach. Not replaced until 1944, these trousers were increasingly enlarged in the seat, hip, and waist area to better adapt them to field and combat use.

Headgear

A peaked visor cap was standard wear with the enlisted man's wool service uniform in the 1920s & 30s. This was the case until the summer of 1940 when procurement of the cap was ended, if only briefly. The enlisted man's wool service cap made through 1940 was built in the traditional style with a wicker frame serving as its foundation (Cap, Service, Wool, Enlisted Men's; Specification QMC 8‐5E, 12 December 1934). Attached to the frame was a leather visor that was russet shade on top and finished with green hatter's dicing on the bottom. A leather sweatband lined the inside of the frame. Attached to the front was a rigid fabric riser providing a peak and a backing to attach the cap ornament. The gilt cap ornament was composed of the US Coat of Arms superimposed on a 1½‐inch disk and was attached to the cap via a screw post and nut that passed through an eyelet in the cover and riser. 18‐ounce olive‐drab shade 33 serge wool was used for the cover fabric which was permanently attached to the cap. A wire spring ran along the circumference of the inside of the crown providing its form. Inside was a lining of olive‐drab green cotton with an oiled silk sweat protector at the center of the crown. A russet leather chinstrap was attached to the front of the cap with two 25‐ligne gilt buttons bearing the US coat of arms.

After the US began to mobilize in preparation for war in the spring of 1940, it was decided that mass issue of the service cap would be curtailed for both economic and practical reasons. Not only would it be too costly to provide a service cap for a greatly expanded army, but its care and storage requirements were excessive for such conditions. Additionally, its awkwardness when worn in vehicles and aircraft made it less than desirable. Conservation would also play a role in the cap's demise as its components, leather, wool, and brass, were critical war materials that were needed for more essential items.

Since 1938 a foldable field cap was authorized for wear by men assigned to aviation and mechanized units (Caps, Field; Specification QMC 8‐114, 25 July 1938). The field cap was issued in lieu of both the enlisted man's wool service cap and olive‐drab service hat (aka campaign hat), both of which proved unwieldy in the tight confines of aircraft and vehicles. After procurement of the wool service cap was stopped in the summer of 1940, a redesigned field cap was approved for general issue in the fall of that year (Caps, Field; Specification dated 11 October 1940).

Made for both field and garrison wear, the olive‐drab field cap of 1940 featured rounded peaks opposed to pointed peaks of the 1938 model. It was fashioned with a bellows crown, a turned‐up curtain that crossed in the front, and a cotton sweatband. The fabric was an 18‐ounce serge wool in olive‐drab shade 33. Army regulations permitted branch of service colored corded braid to be worn on the edge of the cap's skirt, as well as distinguished unit insignia on the left front skirt. This trim was similar to that worn on the olive-drab service hat.

In early 1941, both the olive‐drab and cotton khaki field caps were united under a single specification for simplicity and to help facilitate mass production (Caps, Field, Type I & Type II; Specification 8‐114A, 19 February 1941). By mid‐1942, several types of new field uniforms with corresponding headgear had been developed resulting in the reclassification of the wool service coat and field cap as garrison items. At this time, substitute standard materials were approved for use in the manufacture of the cap and the nomenclature was changed from field to garrison to reflect its new status (Caps, Garrison, Enlisted Men's Type I & Type II, Specification 8‐114B, 2 June 1942). For the most part, the enlisted man's garrison cap remained static until 1950 when it was effectively replaced by a new design.

After nearly a two‐year procurement hiatus, the enlisted man's wool service cap made a limited comeback in the summer of 1942. This time, the cap was procured mainly for aviation cadet use and some other limited applications such as military police. Although it was made under the same specification number (8‐5E), it utilized substitute standard materials, most notably was the coated buckram frame that replaced the traditional wicker, and the use of a plastic sweat protector inside the crown. Despite its limited issue status, the olive-drab service cap remained a popular item and continued to be worn throughout the war years by many enlisted men who purchased them from retail outlets for wear while on leave. Caps sold at retail outlets varied greatly in quality and materials resulting in a variety of appearances. Visors and chinstraps could be patent leather but were typically faux leather and could be russet, black, cordovan, or mahogany shades. Fabric varied from regulation olive‐drab 33 serge wool to fur felt to elastique. In 1946, the Army would again return to the service cap as a standard issue item, this time, utilizing a combination type that featured a frame with interchangeable cotton and wool covers.

Service Coat & Insignia

Coat

In 1939, the enlisted man's wool service coat was revised with the purpose of making it a more useful field garment (Coats, Wool, Service, M‐1939; Specification QMC 8‐31D, 7 February 1940). While the front was virtually indistinguishable from previous models in use since 1926, the back was a completely new design. The front of the new coat retained a single‐breasted front with four 36‐ligne gold colored metal buttons, shoulder and waist darts for shaping, and a roll collar with notched lapels. There were two upper patch pockets, two lower internally hung pockets, and shoulder loops all equipped with 25‐ligne gold colored metal buttons. The traditional four piece back was replaced with a two panel type with pleats on either side that extended from the shoulder to the waist. The back and skirt were separated by a sewn on half belt, and the rear vent now extended from the skirt to the waist. Additionally, the full cotton lining previously used was reduced to the shoulders and sleeves. These revisions to the inside and back of the coat were intended to help facilitate arm movement as well as bending and stooping. Another change involved enlarging the lower pockets and adding bellows seams that dramatically increased carrying capacity. Finally, the shoulder loops were slightly extended and now reached from the shoulder seam to the neck seam.

Initial production of the M‐1939 service coat included brass belt hooks used to support the enlisted man's leather belt even though the new design included a rear cloth half‐belt. By early 1941, the leather belt, worn since the 1920s, was withdrawn as a standard issue item. Concurrently, in March 1941 the belt hooks were eliminated from the service coat. Coats procured through December 1940 were produced with belt hooks and can be identified by the inclusion of bar tack reinforcement stitching above and below the holes where the hook passes through the coat. Throughout the war years, though no longer an article of uniform, many soldiers continued to wear the leather belt when on leave. Remaining a popular item, enlisted men's belts were made available for purchase by commercial outfitters across the country. Thus, coats produced without hooks had them added by soldiers that wanted to wear the belt, and conversely it was common that coats produced with hooks had them removed by soldiers who did not wear the belt.

In early 1941, the Army adopted a standard issue field jacket for the first time, and by the summer of 1942 testing of improved designs was underway. The successful implementation of the wind and water resistant cotton field jacket relegated the wool service coat to garrison use. This development, along with the need to conserve the critical materials brass and wool, resulted in what could be regarded as an economy version of the service coat in the summer of 1942 (Coat, Wool, Serge, M‐1942; Specification PQD 197, 10 July 1942). The new design did away with the pleated back and bellows lower pockets. Additionally, gold colored steel alloy buttons were commonly used. Not long after the specification 197 coat was issued, complaints came in about tightness in the fit of the sleeves and shoulders. These areas were addressed in the final variant of the enlisted man's service coat (Coats, Wool, Serge, Olive‐drab, 18‐oz.; Specification QMC 8‐31E, 29 November 1943) and were implemented in the final production batches of coats made under contracts originally issued in June 1943.

Though the enlisted man's service coat would be issued throughout the World War 2 years and during the early post‐war period in the continental US, it was officially replaced by a short wool field jacket that could also be used in garrison (Jacket, Field, Wool; Specification PQD 437, 12 May 1944). Thus, in the fall of 1944, the wool service coat was declared limited standard to be issued until supplies were exhausted. The wool field jacket resembled British battledress of the period and was essentially developed at the insistence of the ETO command. Considering the recent adoption of wind resistant and water repellent cotton field uniforms, by the time the wool field jacket was issued to the troops after VE day in 1945, a suitable garrison outfit would have been more useful. So, like the service coat of the 1930s, the wool field jacket gradually morphed into a tighter fitting garrison item by the early 1950s. Finally, in 1957, a new four‐pocket service coat in Army Green shade 44 began the phase in process replacing the short olive‐drab wool jacket.

Insignia

Insignia was worn on the collar, lapel, sleeves, and breast of the enlisted man's service coat. On the right collar, the letters "U.S." were worn superimposed on a one‐inch disk in gold colored metal. Personnel assigned to regiments included the regimental number on the disk, and national guard members included both the regimental number and state abbreviation. Gradually, the regimental number requirement was dropped for all federalized units as a matter of wartime practicality. On the left collar, the insignia of arm or service was worn superimposed on a one inch GCM disk. Distinctive insignia were worn on the upper part of both lapels and could represent regiments, separate battalions, or separate companies. Distinctive insignia were composed of heraldic symbols enameled on a metallic crest and typically consisted of a unit's coat of arms, or similar devices having historical significance connected with the organization.

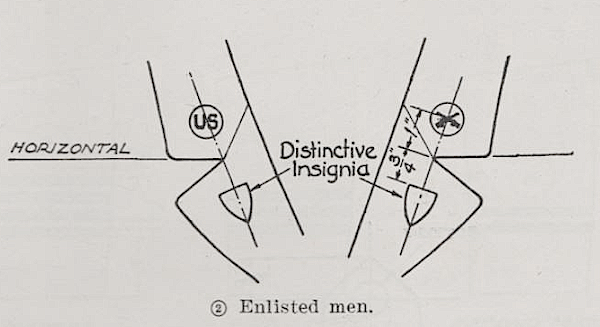

Drawing showing the type and placement of collar and lapel insignia on the enlisted man's wool service coat from Army Regulations No. 600‐40, Wearing of the Service Uniform, dated 28 August 1941.

Illustrations from Army Regulations No. 600‐35, Prescribed Service Uniform, dated 10 November 1941 showing enlisted men's collar insignia. The top row shows the various types of "US" disks. As National Guard units were federalized, state abbreviations and regimental numbers were dropped from the disk. Below are branch of service disks. As the war progressed and as the need arose, new branch of service insignia were created.

Insignia of grade (aka chevrons) were made up with olive‐drab wool chevrons, arcs, and lozenges cut and sewn to a dark blue wool background or embroidered using olive‐drab thread on a dark blue background. They were worn point up on the sleeves of the shirt, coat, and overcoat midway between the shoulder and elbow to denote a soldier's pay grade (rank). First World War service chevrons were worn on the left sleeve four inches from the cuff with the point facing down except when worn with service stripes in which case they were to be worn ½‐inch above the uppermost service stripe. Each service chevron represented six months in Theater of Operations. Chevrons for wounds received in the First World War were worn on the right sleeve with the point facing four inches from the cuff. One chevron was worn for each wound received. World War service and wound chevrons were made of gold lace or bullion on an olive-drab background.

Service stripes were worn on the outside of the lower left sleeve with each stripe representing three years of honorable federal service. Placement was at an angle of 45‐degrees with the lower end being toward the inside seam of the sleeve and placed four‐inches from the end of the sleeve. Additional stripes were worn above and parallel to the first stripe. Service stripes were constructed from the same materials as the insignia of grade discussed above.

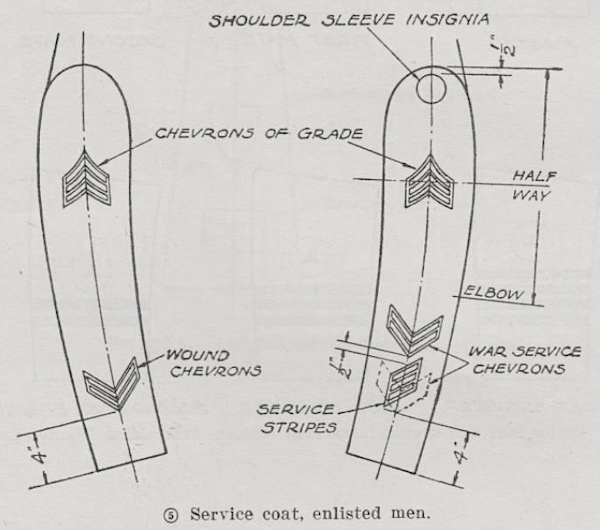

Colorized drawings from Army Regulations No. 600‐35, Prescribed Service Uniform, dated 10 November 1941 showing sleeve insignia worn on the enlisted man's wool shirt, service coat, and overcoat. Rows 1‐2 show insignia of grade worn midway between the shoulder and elbow on both sleeves. Row 3 shows technician's grades added to Army Regulations via change No. 1, dated 4 September 1942. Row 4 shows FIrst World War wound chevrons and service stripes worn four‐inches from the cuff.

Shoulder sleeve insignia were textile emblems made of wool, felt, or embroidered and were used to identify different units such as Armies, Army corps, Divisions, Departments, Districts, and Commands. Army regulations allowed SSI to be worn ½‐inch below the top of the shoulder seam on the left sleeve of the service coat and overcoat. Designs were made in various shapes and sizes, were usually brightly colored, and had to be approved by the War Department before being put into use. First used during World War 1 on a limited basis, the use of SSI during the World War 2 era proliferated greatly.

Drawings showing the various types and placement of cloth sleeve insignia on the enlisted man's wool service coat from Army Regulations No. 600‐40, Wearing of the Service Uniform, dated 28 August 1941.

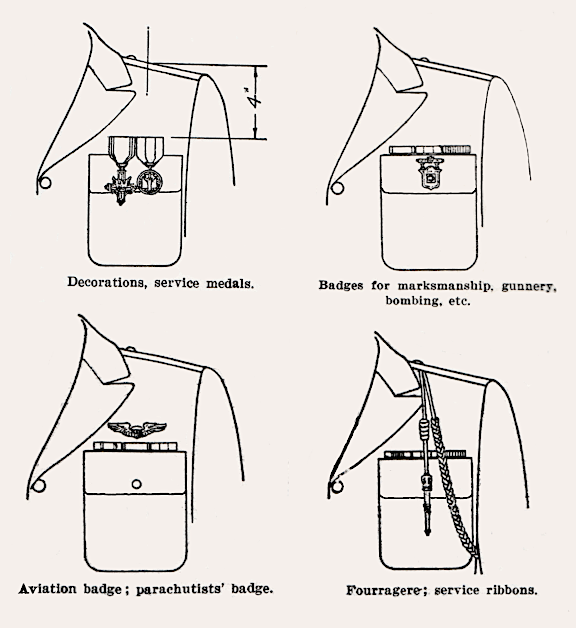

Decorations and service medals were worn above the left breast pocket in an order of precedence. These were typically not worn unless prescribed by the commanding officer for some specific event such as parades, reviews, inspections, and funerals, or during ceremonial and social occasions of a general and formal nature. Service ribbons were worn above the left breast pocket in an order of precedence. Three ribbons were worn in a horizontal line per row and could be attached via a bar or sewn on. Service ribbons were not to be worn at the same time as decorations and service medals. Decorations, service medals, and service ribbons were not worn on the field uniform.

Badges were worn on the left breast. Some types, such as aviation and parachutist badges, were worn above the line of medals or service ribbons. Others, such as marksmanship qualification, gunnery, and bombing, were below the line of medals or service ribbons, usually on the left pocket flap. The Fourragere is both an organizational and an individual decoration and worn on appropriate occasions similar to decorations and service medals. It is attached to the left shoulder by fastening the buttonhole thereof to the left shoulder loop button, under the shoulder loop, passing the Fourragerre under the left arm, and attaching the loop on the ferret end to the shoulder loop button, allowing the ferret to hang down in front.

Illustrations taken from Army Regulations No. 600‐40, Wearing of the Service Uniform, dated 28 August 1941 showing how decorations, service medals, service ribbons, badges, and the fourragerre were worn on the service coat.

Shirts & Necktie

Shirts

The Army wore a pullover olive‐drab shirt until 1933 when a fully opening coat‐style design replaced it (Shirts, Flannel, Olive‐drab, Coat‐style; specification QMC 8‐26C, 4 October 1933). In 1937, specifications were drawn up for a new refined dress‐style shirt that could be worn as an alternative to the flannel shirt in garrison or in warmer conditions. The new shirt was made in olive‐drab shade 31 worsted wool and featured a plain weave (Shirt, Worsted, Olive‐drab; Specification QMC 8‐108, 2 August 1937). Styling included a standing and falling collar, seven button placket front, rear shoulder yoke, and shirt-style cuffs. Pockets and flaps were both mitered at the lower corners. Gone were the elbow patches and pencil pocket common to previous shirts. Approved in the same year, the restyled shirt and transition to trousers gave the Army service uniform a more modern, sophisticated look.