U.S. Army Men's Overcoats

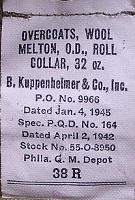

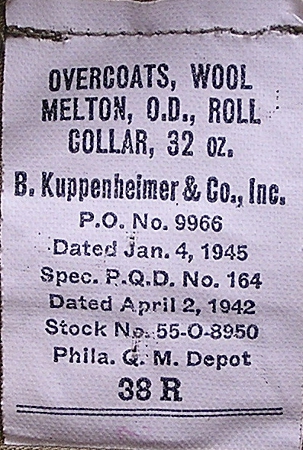

32 Ounce Roll Collar Olive Drab Melton Wool Overcoat

Specification PQD 164 Dated 2 April 1942

Stock No. 55-O-8900 - 55-O-9115

| ORGANIZATION, UNITS, SPECIALISTS, & STATUSES | ZONE OF INTERIOR |

|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

| Key Visual ID | Primary Materials | Fasteners | Color | Labeling |

| This version of the Enlisted Man's overcoat can easily be recognized due to its use of plastic buttons throughout. | 32 Ounce Melton Wool Melton Wool - A medium to heavy weight wool in the 20 to 30 ounce per square yard range, typically used in making blankets or heavy outer wear. The tight weave is hidden by a heavy brushed nap that is closely cropped, giving the material a smooth appearing finish. Partial Liner: 8.2 ounce Cotton Twill. | There were 16 buttons: 8 x double breasted front closure, 1 x front skirt closure tab, 3 x rear skirt vent, 1 x 2 shoulder loops, 1 x 2 inside access slits. Later production coats had an anchor button on the inside front that fastened the two halves of the coat together from the inside. | Olive Drab shade 33. | The size tariff was ink stamped on the lining at the nape of the neck. |

| Treatments | Approx. Contract Run | Preceded By | Replaced By | Companion Garments |

| N/A. | July 8, 1942 to February 25, 1946. | 32 Ounce Roll Collar Olive Drab Melton Wool Overcoat, Spec. 8-51B dated 11 March 1940. | Olive Drab 7 Field Overcoat with Removable Liner, Spec. PQD 587 Pattern Date 6 June 1946. 32 Ounce Roll Collar Wool Overcoat, Spec. 8-51C dated 10 October 1947. | Worn over the Enlisted Man's Class A Uniform  The Enlisted Man's Class A Service Uniform consisted of the serge wool coat & trousers, coat-style cotton or flannel shirt, and was worn with either the garrison cap (left), or service cap (right). in cold climate conditions. |

(hover for expanded view)

The WWII melton woolMelton Wool - A medium to heavy weight wool in the 20 to 30 ounce per square yard range, typically used in making blankets or heavy outer wear. The tight weave is hidden by a heavy brushed nap that is closely cropped, giving the material a smooth appearing finish. overcoat originated in 1927 when the enlisted man's winter wool uniform went through major design changes. Dating back to WWI, the melton overcoat was a late 19th-century, double breasted, ulster-style design with a standing and falling collar. The new overcoat, approved on 3 March 1927, was notably different in that it was redesigned with more up to date features. The new look included a notched lapel, and convertible, roll collar. These updated features would remain with the overcoat until it was discontinued. Specification PQD 164 was a variant of the WWII overcoat brought about by the urgent need, early in the war, to conserve critical strategic military commodities. The enormous consumptive demand placed on wool and brass by the massive, 6 3/4 pound, full length, overcoat was further compounded by its mandatory issue status. These characteristics made it a priority target for conservation efforts. At the outset of the war concerns arose among conservation officials over the problem of meeting production requirements for wool uniforms. Wool conservation quickly became an urgent priority necessitated by the needs of new recruits, preparation for a planned massive future manpower build up, and to counter the growing threat that Axis forces posed to shipping lanes from both England and Australia. The enlisted man's wool uniform, produced with 32 ounce melton, 18 ounce serge, and 10 1/2 ounce shirting flannel, combined for more than 80% of the Army's wool requirement. Early discussions brought about the proposal to reduce the weight of the woolen uniform. This idea, however, was opposed by the Quartermaster Corps because US winter uniforms were already lighter in weight than those of other countries. By late March 1942 a compromise solution was agreed upon by conservation officials and the Quartermaster Corps; the amount of reprocessed wool would be increased in the overcoat. There was reluctance even to take this measure because the overcoat was already constructed with 35% reprocessed wool. Nevertheless, a 15% further increase in reprocessed wool content was agreed upon, bringing the total reprocessed wool content up to 50%. The use of reprocessed wool involved gathering cuttings, scraps, or other unused cloth, and recycling this material into the production of new cloth. The process had the effect of causing the new material to lose some of its insulating properties. Shortly thereafter, on 2 April 1942, specification 164 was drawn up for an overcoat that would make use of the newly revised wool mixture. Production contracts wouldn't be issued until July when the new material became available. Copper, brass, and bronze were other essential materials that quickly fell under the strain of the expanding Army and defense programs that began in 1940. Aside from the primary need in ordnance manufacture, copper metals were also consumed by a wide variety of military clothing and equipment. This included web gear, tentage, buckles, and uniform buttons. As a result, unifroms utilizing copper fell under the conservation effort of the War Production Board. Projected shortages in copper required that substitutes be developed and utilized as long as the alternative didn't compromise an item's function. In response, two separate efforts designed to conserve brass were applied to the wool overcoat: First, was a successful Quartermaster effort to salvage and refurbish WWI era overcoat buttons. Second, was the development of an entirely new button composed of olive drab plastic and steel shank that was intended to completely replace the current gilt brass type. Thusly, beginning in March 1942 both refurbished blackened brass WWI buttons and the new plastic type were utilized in production. The early use of these buttons were incorporated into the final contract runs of specification 8-51B that occurred in March and May 1942. By the time the overcoat specification was redrawn on April 2, 1942, only a small number of gilt and blackened brass buttons remained far enough in the pipeline to be utilized in production. When production resumed in July under the new specification, the few remaining metallic buttons on hand were used up as the new plastic type became predominant. Collectors should note that the melton wool overcoat was manufactured under specifications 8-51B and 164 utilizing all three types of buttons; blackened brass, gilt, and plastic. With the emphasis on the development of suitable field clothing throughout the war, by 1943 the melton overcoat was mostly relegated to dress, parade, and furlough wear. As events unfolded in the ETO during the winter of 1944-45, the Melton overcoat was unexpectedly called into front line service. | Prior to the onset of winter, failure to build up an adequate supply of the new, warmer M-1943/wool field jacket combo, and the decision to rely on the olive drab field jacket, left troops woefully short of warm clothing. Out of necessity soldiers became dependent upon their melton overcoats for warmth in the field. Photographic evidence from the ETO is plentiful showing the melton overcoat in use at the front in 1944-45 A new feature was added in late 1944 - early 1945 in the form of an anchor button located on the inside left facing of the coat. This large, sewn through button was parallel to the center row button hole on the right side of the coat, and served to fasten the overlapping layers together from the inside. In mid-1942 a developmental plan was initiated to replace the melton wool overcoat with a two-piece trench coat design consisting of a cotton shell and a light, removable wool liner. The idea was that this type of garment would be more versatile; it could be worn in a wider temperature range, offer some moisture protection allowing it to replace the general issue raincoat in some circumstances. This in turn would help conserve both wool, and synthetic rubber, which was also in short supply. In July 1942 a quantity of new enlisted man's trench coats were purchased and tested in the field throughout the winter of 42-43. By the fall of 1943 further development of the enlisted man's trench coat was stopped due to production requirements of the newly adopted combat field uniform, of which several components relied on cotton fabric in their construction. Also, by this time adequate stocks of wool had been built up to meet overcoat requirements. In the interim an officer's trench coat was fully developed and approved (Officer's Field Overcoat, spec. PQD 314 dated 17 December 1942). Work on the enlisted man's trench coat was reinitiated in April 1944, with further development being patterned around the officer's coat. Final development and approval of an enlisted man's overcoat would not occur, however, until after the war ended. The final design (Olive Drab 7 Field Overcoat with Removable Liner, Spec. PQD 587, Pattern date 4 June 1946) was essentially a simplified version of the officer's trench coat, but lacked such details as the right shoulder storm flap and front skirt retaining buttons. The enlisted man's trench coat went on to be produced in great quantities, and saw extensive use in the Korean War. Wool overcoat production continued into 1946, and in mid-1945 gilt buttons began to reappear. In the spring of 1946 further wool overcoat procurement seems to have halted in order to focus on the final development and contracting of the new cotton overcoat with liner. Then, wool overcoat resumed again in 1947, presumably to expend remaining stocks of 32 ounce wool and gilt buttons. Tags on surviving overcoats seem to indicate that the final procurements of wool overcoats occurred in 1947 and 1948 and were contracted by the New York Quartermaster purchasing Office under specification 8-51C, dated 10 October 1947. Melton wool overcoats are often found fully embellished with insignia. Upon honorable discharge, enlisted men were entitled to an issued overcoat when one was required for warmth. During the discharge process many of them had a variety of insignia applied to them in addition to the usual rank and unit shoulder patches. For example, unit citations, specialist designations, as well as the honorable discharge emblem (Ruptured Duck A common occurrence in the WWII period was to have the big Melton overcoat cut down and reworked into an M-1926 officer's short field overcoat. The M-1926 was an unlined mackinaw-style coat with a belt, shawl collar, and two patch and flap pockets at the hip. After the overcoat was cut down to size, excess fabric that had been the coat's skirt was used to make the patch pockets, belt and loops, and sometimes to rework the lapel collar into a shawl type. Buttons were replaced with an officer's type. The quality and extent of the conversions varied. Converted Melton overcoats can be visually identified by the presence of their cotton lining, whereas the original M-1926's did not have a lining. Both the 8-51B and 164 specification overcoats can be found converted to the officer's M-1926 short style. |