US Army Uniform Profile

Enlisted Men's Australian Made Reverse Lend Lease Wool Service Uniform

(1942‐44)

Point or touch each image for descriptions

Australian Made Reverse Lend Lease Uniforms (1942‐44)

Background

For the most part, reverse lend lease is a term that refers to the reciprocal aid provided to U.S. forces by one of the Allied Nations during World War II. Its origins began with the passage of the Lend Lease Act on 11 March 1941 allowing the U.S. government to provide military aid to nations integral its own national defense. Initially, the lend lease program enabled the U.S. to provide much needed weapons and other aid to Britain when the nation stood alone at war against Germany. Later, this crucial aid was extended to other allies such as the Soviet Union. After the U.S. entered the war in December 1941, the idea of lend lease came full circle with the concept of reverse lend lease where recipients of U.S. aid would in return provide help to U.S. forces in the form of needed goods and services. This was necessitated by the U.S. sending troops to far‐flung, difficult to supply places such as Iceland, New Zealand, New Caledonia, and Australia. In March 1942, an informal agreement was signed among the Allied nations called the UK‐US Mutual Aid Agreement, or Master Agreement, in which the signees agreed to provide for the common defense of one another to the maximum availability that each nations resources would allow. Thus, the original lend lease concept had grown into a mutual agreement among Allied nations to marshal resources in order to defeat their common enemies.

Later, in September 1942, keeping in spirit with the Master Agreement, Australia signed a formal agreement with the United States. This contract stipulated that the Australian Government would supply military equipment, munitions, general supplies, and services to U.S. forces. Additionally, the Government would engage in the construction of military projects and capital works required for the common war effort. Australia would provide these services to U.S. troops in Australia, its territories, and the Southwest Pacific Area, in general, as needed. This reciprocal aid would play an important role in helping to transform Australia into a major base of operations for the American led counteroffensive to expel Japanese forces from the Southwest Pacific. U.S. forces were rushed to the continent in early 1942 to prevent Japan's attempt to isolate Australia by cutting its lines of supply. This critical situation resulted in the Battle of the Coral Sea, and the Allied invasions of New Guinea and the Solomon Islands that were designed to remove the immediate Japanese threat from Australia's shores.

Australia's contribution to reverse lend lease was enormous and amounted to 20% of its total war expenditures. It's biggest expense as a percentage of its reverse lend lease costs was providing U.S. forces with food. Government and industry provided a wide range of critical goods and services to U.S. forces stationed there:

Services

- Transportation by land, sea, and air.

- Postal, telephone, and telegraph facilities.

- Maintenance of aircraft and aero engines.

Capital Works

- Construction of camps, airfields, wharfs, barracks, and hospitals.

Supplies

- Munitions.

- Refrigeration units, aircraft parts, small ships, and engines.

- Food and clothing.

Most U.S. service personnel arriving in Australia in early 1942 were dressed for tropical conditions and wore either summer khaki cotton uniforms or cotton herringbone twill uniforms. Soon it was realized that Australia had a winter season spanning from June through July that would require warmer clothing than what GIs had brought with them. This oversight created an immediate need for wool clothing. Fortunately, Australia was the world's largest wool producer and even though Great Britain took a significant portion of this output, the yield was still sufficient to supplement the needs of the American Army as well. To help conserve wool usage, the U.S. Army restricted the wearing of wool uniforms to the winter months thus prolonging their service life. Initially, the primary garments needed consisted of wool jackets, shirts, trousers, undergarments, and socks. To meet these requirements, the Australian garment industry would have to undergo substantial expansion. Additionally, a few other obstacles would have to be overcome before the manufacture of Army clothing could begin. For example, there were no technical specifications or patterns with which garments could be cut. To remedy this situation, Quartermaster personnel relied upon Australian Army technicians to essentially reverse engineer garments of various types in order to create workable patterns. This solution was used until specifications and patterns arrived from the U.S. several months later. Also, serious problems would be encountered manufacturing fabrics and dyes that were able to meet U.S. Army specifications.

Once specifications and patterns arrived from the U.S., fulfilling the requirements set forth therein still posed a major challenge. Specifications, patterns, and manufacturing methods often had to be modified to meet the needs of local contractors and for the types of fabrics that were available. In fact, the inability to obtain or produce fabrics and dye colors that were up to standards led to a general dissatisfaction with many of the items produced. This reality resulted in the discontinuation of some items after only limited attempts to produce them. Examination of surviving examples of various articles of clothing reveals that, for the most part, patterns were generally quite good with finished goods largely resembling their American made counterparts. On the other hand, the fabrics used were often very different with the type of weave and color varying considerably. The production of Army shoes faced similar challenges as did clothing. The Australian shoe industry had to go through some major changes in order to produce shoes according to American sizing standards. However, once Army Munson lasts and American machinery arrived, shoe production was generally satisfactory and nearly one and a half million pairs were made for the Army.

Though most soldiers were already dressed in cotton uniforms, some cotton items were produced under Australia's reverse lend lease program. These mostly consisted of one and two‐piece herringbone twill outfits, both the utility type and special jungle versions. While a wide variety of uniform articles were manufactured in Australia, the American field jacket was conspicuously absent from this group. This item possessed a tightly woven wind‐resistant cotton outer shell treated with water repellent chemicals. This fabric was considered a key element of its functionality. However, a comparable substitute material could neither be manufactured to satisfactory specifications nor in the needed quantity to be viable under the Australian clothing program. This resulted in the development of a waist‐length wool jacket reminiscent of the British or Australian battle jackets but still retaining some American features. All in all, the Australian clothing program under reverse lend lease was considered very successful and contributed greatly toward keeping their American allies clothed and shoed properly. As MacArthur's forces moved northward and shipping and supply lines improved, the need for reverse lend lease clothing diminished. After mid‐1944 Australian clothing manufacturing began to move away from Army clothing to Navy production. Millions of items in all were produced for the Army with the following list showing some general categories of the various types of items manufactured:

Army clothing and quantity delivered under Australian reverse lend lease through June 30, 1944

- Caps & hats (210,172)

- Chevrons & other insignia (971,224)

- Pairs of Gloves (604,946)

- Helmets (34,000)

- Head nets (697,600)

- Jackets (484,056)

- Shirts (488,668)

- Pairs of Socks (7,552,524)

- Sweaters (260,872)

- Underwear (461,000)

- Ties (1,235,000)

- Trousers (316,694)

- Boots & shoes (1,445,537)

Headgear

By early 1942 the garrison cap was standard issue for enlisted men. It was Army regulation that the cap be made of the same material as the service coat. In general appearance, the Australian made enlisted man's garrison cap was a good representation of its American made counterpart (specification QMC 8‐114A, dated 19 February 1941) having curved peaks, a turned‐up curtain that crossed in the front, and a center gusset. However, the cap was fabricated out of an entirely different material than the olive‐drab shade 33, 18‐ounce serge wool specified for enlisted men's caps and service coats. Like many of the garments made under reverse lend lease, items had to be made from the fabrics that were available and in this case it was the same napped wool used to fashion the substitute standard wool field jacket developed in Australia for U.S. forces.

Jacket

Of the assorted clothing items produced under Australian reverse lend lease, the short wool jacket is the most recognizable. Development of this jacket proceeded as a substitute for the American field jacket, which had a wind and water‐proof cotton exterior and integral wool flannel lining. It was determined that there would not be an adequate supply of cotton to produce the outer shell in sufficient quantity, nor would the water‐proofing chemicals be available that were needed to treat the fabric. Thus, production not being feasible, an alternative was sought. The result was a waist‐length, woolen jacket having a short nap that was fashioned in the British battledress style. It strongly resembled Commonwealth jackets in that it was unlined, had a bottom waistband, two large, expandable breast pockets, and concealed buttons under the front opening and pocket flaps. The design did keep a few American features like hip and wrist tightening tabs and flat buttons. Commonwealth dish‐style buttons were used where they were concealed under the pocket flaps and main opening. However, where exposed on the wrists and front belt line, flat, American‐style buttons were used so that U.S. personnel wearing the jacket would not be confused with commonwealth troops.

The napped wool enlisted man's jacket was, by far, the most common type produced. However, some notable variations of the substitute field jacket were also made. One such type used a darker, napless fabric that sought to replicate the olive‐drab shade 33 serge wool used to make the enlisted man's service coat. Another variation made for officers also existed. This jacket had a dark, olive‐drab shade 51 wool elastique exterior and was fully lined with a rayon‐like fabric. In total, a large number of these jackets were produced, some 270,000 estimated, and were worn by Army, Air Force, and Marine personnel. Surviving jackets are commonly seen with Far East Forces, Fifth Army Air Force, and First Marine Division shoulder sleeve insignia.

Trousers

Australian made trousers were relatively short‐lived compared to some of the other items made for U.S. enlisted men. This is because of a general dissatisfaction with the appearance that stemmed from the native industry's inability to mass produce trousers and maintain a uniform fit across sizes. Problems persisted to the extent that contracts were permanently cancelled in mid‐1943. These trousers were manufactured according to the U.S. Army specification for Trousers, Enlisted Men's, Service, Olive‐drab (specification QMC 8‐83B, dated 9 November 1937). The color was very close to the olive‐drab shade 32 used to produce American trousers. This color was referred to as Olive‐Drab Light Shade. However, an entirely new fabric had to be developed before trouser production could begin. This need arose due to the inability of Australian industry to manufacture a satisfactory copy of the American fabric. The Army rejected existing fabrics in use in order to ensure its soldiers were dressed in a distinctive uniform that would minimize any confusion with other allied soldiers. In all, approximately 420,000 pairs of trousers were delivered by Australian industry. Most surviving examples show a contract date of 1942.

Shirt

A knitted wool shirt was developed to go with the wool jacket and trousers. The shirt was patterned on the standard enlisted man's khaki cotton summer shirt (Specification QMC 6‐241, dated 29 November 1938) but instead of the 8.2‐ounce khaki cotton shirting, an entirely different fabric was used. This was a light, knitted wool fabric that offered superior breathability. Considered a successful development, approximately 1,100,000 knitted wool shirts were delivered by Australian manufacturers. At first glance, the shirt resembles the standard enlisted man's wool shirt of the period but with a color slightly off from the olive‐drab shade 31 prescribed by specification. Close examination reveals that the fabric has a very different weight and texture than the 10.5‐ounce shirting flannel used in the standard issue American wool shirt.

Sweater

The sweater produced by Australian industry under reverse lend lease was based on the U.S. Army Quartermaster specification PQD 111, dated 22 December 1941. This sweater, designated the Type 2, was a V‐neck style made up in a shaker knit and was worn by both Army and Air Force personnel. The Australian sweater was true to the American version except for its color, which was much lighter than specified. In fact, it was more of a light green opposed to the dark olive‐drab that the American sweater usually appeared in. This particular item represents a clear example of the difficulty Australian industry faced in producing dyes that met Army specifications. Approximately 260,872 sweaters were produced under reverse lend lease. At this time, only the V‐neck variety has been observed, so it is unknown if other types were produced.

Undergarments, Overgarments & Other Items

Large numbers of undergarments were also produced by Australia under reverse lend lease. The basic set was a medium‐weight, cotton‐wool blend consisting of a short‐sleeved undershirt and long drawers. The Australian undershirt differed from its American equivalent in that the American garment had long sleeves. Undergarments were made in natural colors due to the lack of proper dyes. About 461,000 sets of Australian reverse lend lease underwear were made.

Enlisted men's woolen overcoats (not shown) were also made under reverse lend lease. These coats were fashioned on the Quartermaster Corps specification for Overcoats, Enlisted Men's, Woolen, Olive‐drab, Roll Collar (QMC 8-51B, dated 11 March 1940) and were faithful representations of the American made coats with the type of fabric and color being similar to the wool field jacket and garrison cap.

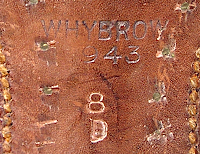

In addition to clothing, various kinds of web equipment were also contracted in Australia. Among these were the M-1937 enlisted man's web belt that was worn with all types of uniforms during the war. Samples examined indicate that Australian made belts were patterned from the Quartermaster Corps specification JQD 19, dated 19 September 1941. The belt portion is true to the specification showing an acceptable weave, a 1¼-inch width, and is typically marked Made in Australia. No markings have been observed on the buckles thus far and its unknown if manufacture of this component occurred in Australia. Buckles do show a combination of standard and substitute standard materials including brass and steel alloy which is consistent with the noted specification.

Footwear

Shoe production was perhaps the greatest achievement of Australia's reverse lend lease clothing program. By late 1944 60,000 pairs of shoes were being manufactured per month and over 1,500,000 pairs of shoes were made in the previous two and a half years. This output met a substantial part of the U.S. Military's regional needs. Before production could get underway, the Australian shoe industry had to undergo a significant transformation in order to make U.S. sized shoes. Australian army shoes only came in full sizes and in two widths, while American shoes included half sizes and several different widths for each size. Production of shoes began only after a set of Army Munson lasts and American shoe making machinery arrived from the U.S. in April 1942. Additionally, The General Supplies Branch of the Office of the Quartermaster General Supply Division provided extensive technical help to the Australian Shoe industry.

Australian plants turned out several kinds of Army shoes including standard service shoes, hobnailed shoes, and a type having rubber soles with heavy treads. Large numbers of hobnail shoes were manufactured in Australia because soldiers preferred them for wear in the wet, slippery terrain often encountered in the Southwest Pacific. Also, these shoes were often difficult to get from the United States. The Australian made hobnail shoe presented accurate to the design of the American shoe. However, there were notable differences: the Australian shoe was made with pebbled leather, the color was lighter than the russet shade specified for American Army shoes, and the hobnails were of a different design than was commonly used in America. In late 1944, shoe production started for the Navy after the importation of the Army's new double buckle boot reduced demand.

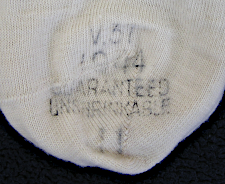

The manufacture of Army socks was another critical endeavor undertaken in Australia. Considered successful, the startup of production, however, faced challenges similar to those faced by the shoe industry. Namely, the Australian hosiery industry had to be reorganized in order make lightweight socks as opposed to the ribbed heavyweight socks designed to fill out oversized Australian Army shoes. Additionally, manufacturers had their own shaping, sizing, and pressing standards. The use of different sizing boards among makers caused variations in fit in socks marked the same size. This problem led the General Supplies Branch of the Office of the Quartermaster General to prescribe the standardization of sizing boards across the Australian hosiery industry. Shortages of good dyes forced the mills to produce socks in natural colors. Also, shortages of the chemicals used to prevent shrinkage shortened the expected service life of socks. At the peak of production in 1944, 350,000 pairs of socks per month were being turned out. In the end, Australian factories produced about 8,000,000 pairs of standard lightweight army socks.

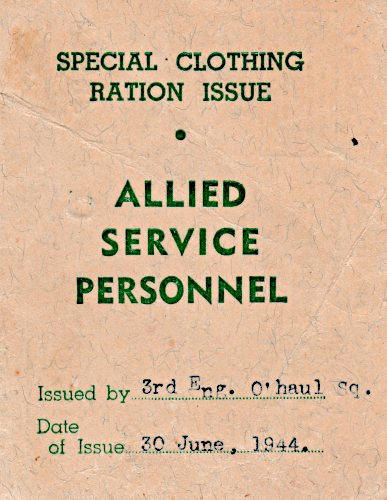

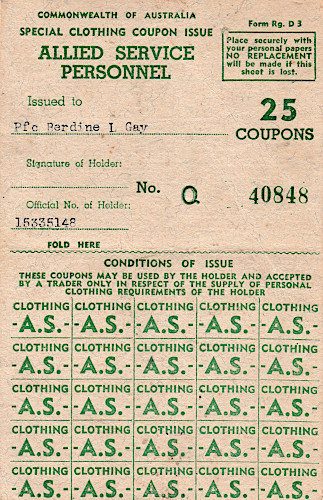

Issue

Little is known exactly how reverse lend lease clothing was issued. However, Special Clothing Ration Issue books have been discovered among the possessions of enlisted soldiers who served in the Pacific Theater. These were small books printed by the Australian Government containing coupons that could be exchanged for clothing and were distributed to Allied personnel through the chain of command. Information from the books suggest they were issued in bulk to various Army units stationed on the continent. Each book was serial numbered and had spaces for the name and service number of the soldier to be typed in before final issue. There were twenty‐five coupons in each book, but the value each coupon held in relation to various clothing items is unknown. According to the book, the coupons were to be taken to a trader where they could be exchanged for clothing. Whether there were additional ways reverse lend lease clothing was distributed to enlisted men is unknown.

All types of uniform components were made for officers in Australia. Officer's clothes usually had a commercial maker's label on the inside instead of the government contract label and inspector's markings found on enlisted men's clothes. U.S. officers customarily purchased their own uniforms with a clothing allowance that was part of their pay. Whether U.S. Officers paid money for their clothing purchases while in Australia or received the same coupon books as enlisted men or some other type of voucher for clothing is currently unknown.

Conclusion

As acknowledged in Army historical volumes, the Australian reverse lend lease clothing program was considered highly successful despite some of the difficulties it encountered. The fact that Australian industry was able to produce a significant portion of clothing provided to U.S. forces stationed on the continent outweighed the frequent inability to produce goods that met U.S. Army specifications and the dissatisfaction that arose from the situation. The main causes of difficulty were often beyond any controllable factor and included conditions such as the lack of necessary machinery, chemicals, or natural resources needed to produce certain types of fabrics and dyestuffs. The volume of articles produced by Australian industry speaks for itself as many of these items survive today, brought home by GIs as part of their clothing discharge allowance. The most prevalent and easily recognized item being the wool field jacket, which was often fully embellished with insignia applied during the discharge process.

The article of clothing that garners the most attention today is the short battle‐style jacket made for U.S. forces. This jacket is generally sought after by militaria collectors and historians, being recognized as a significant article of uniform worn in the Pacific Theater of Operations. Although discussed in post‐war Army Quartermaster histories, the jacket's actual name and proper nomenclature is not mentioned and has gone unused and apparently unknown among knowledgeable collectors and historians. As mentioned, the jacket was also worn by Marines and today some collectors refer to Australian jackets attributed to Marines as "Vandegrift Jackets" (named after the Marine Corps Commandant during WW2). Army histories describe the jacket as a joint Army and Australian development. Although, the establishment of the Marine Corps Equipment Board, active at the time, actuated cooperation in uniform development with the Army, it remains unknown if the Marine Corps played any role in developing the Australian jacket. What is certain is that the USMC adopted a similar jacket for officers in 1944 called Jacket, Field, Service, Winter that was clearly patterned after the Australian made jacket. Briefly, in 1945, the short, jacketed uniform replaced the traditional four‐pocket type for Marine Corps officers. Then in early 1946, when the jacket was also approved for enlisted men, both the jacket and four‐pocket coats were maintained in the USMC wardrobe, one to be used as a field uniform and the other a garrison uniform respectively. The Army similarly referred to this type of jacket as a field jacket as was the case with the short wool types manufactured in Britain during the war that collectors and historians commonly refer to as ETO jackets.

After eighty plus years there is still much to learn about Australian reverse lend lease uniforms. Though generalities are known, much detail is missing from the knowledge base. For example, there are few if any specifics about the official nomenclature of the various items, types of fabrics used, and how clothing reached the end user. It's hoped that more can be learned about these items, especially the extraordinary ones, such as the wool field jacket, knit shirt, and one and two‐piece herringbone twill jungle suits. It should be mentioned that the enlisted man's uniform components shown in this presentation represent only some the uniform items made in Australia during WW2. In addition to herringbone twill outfits, uniforms were made for officers as well, including service caps and coats, trousers, shoes, and field jackets. There were also flying clothes made for the Air Force including flight jackets. Most Australian made clothing is found one or a few items at a time in the remaining possessions of GIs who passed through Australia at some point in their service. This suggest that rarely, if ever, a GI would be outfitted in an entire Australian made uniform. Hopefully, the future will bring more answers to the Australian reverse lend lease clothing program so that we may have a fuller understanding of these historic uniforms.

Bibliography

- Unattributed. Seventeenth Report To Congress On Lend‐Lease Operations, Reverse Lend‐Lease From The British Commonwealth of Nations. U.S. Government Printing Office: 1944.

- Stauffer, Alvin P. United States Army In World War II, The Technical Services, The Quartermaster Corps: Operations In The War Against Japan. Center Of Military History, United State Army, Washington, D.C., 1990.

- Unattributed. Lend‐Lease Became Mutual Aid. Australian Newspaper Argus. Thursday, June 28, 1945.

- Marine Corps Letter of Instruction No. 1274. Service Jackets. 9 May 1946. 1135-70-40, A-134-ms.