US Army Uniform Profile

Enlisted Men's Khaki Cotton Uniform

(1941‐42)

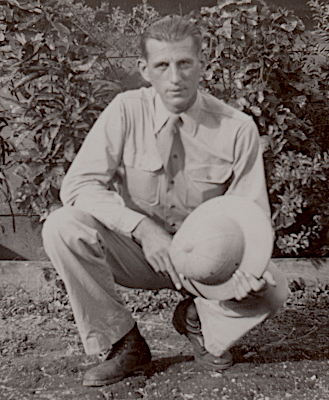

Part Ⅰ : Service Uniform

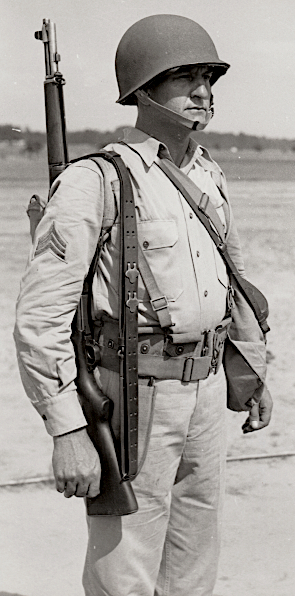

Part Ⅱ : Field Uniform Dismounted (Shown Below)

Point or touch each image for caption.

US Army Enlisted Men's Khaki Cotton Uniform (1941‐42)

Background

The enlisted man's khaki cotton summer uniform went through a number of classification changes and design modifications during its WW2 service life. In the pre‐war and early WW2 period it was a multi‐purpose uniform worn for garrison, field, and combat. Shortly after the war started, however, it was removed from the combat role. For a period, from mid‐1942 to 1943, two versions of the uniform were produced, a standard one for stateside use, and a modified version having gas protection features for overseas use. Then, from mid‐1943 to late 1944, in order to reduce supply strain, the uniform was produced exclusively with gas protection features. By the end of 1944, however, gas protection features were removed for good as the outfit was reclassified as a garrison uniform. Throughout its long life, the khaki cotton uniform has been known by various names including summer service uniform, chinos, suntan uniform, and simply khakis.

The khaki uniform went through additional modifications in order to implement improvements as well as conserve resources and expedite production. All essential components of the uniform were affected including headgear, shirts, and trousers. These changes involved such things as improving the fit of the trousers, allowing alternative construction methods in order to increase trouser production, conserving material by reducing the weight of the shirt, and developing more practical headgear.

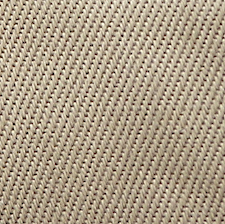

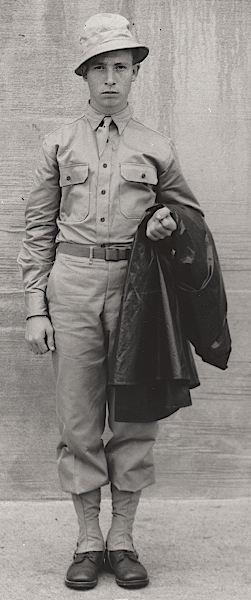

Designed for summer wear, the khaki uniform was a simple affair consisting primarily of a long‐sleeve shirt and trousers, both made in 8.2‐ounce khaki twill. What distinguished field use from garrison use was the type of headgear and footwear worn with the shirt and trousers. If field wear was required, garrison shoes or low quarter shoes were exchanged for standard service shoes and canvas leggings. Additionally, the garrison cap or service cap was replaced with either a fiber sun helmet, cotton field hat, or steel helmet. In the feature presented above, the field version of the khaki cotton uniform is illustrated. A link to the garrison version is provided HERE.

The configuration of the WW2 era khaki cotton summer uniform was relatively new with specifications having been set for the trousers in November 1937 and the shirt in November 1938. Prior to 1938, the enlisted man's summer uniform consisted of an unlined, four‐pocket service coat (Coat, Cotton, Khaki, Enlisted Man's; Specification QMC 6‐66A, 2 October 1936) worn over a lightweight oxford cloth shirt (Shirt, Cotton, Khaki, Oxford‐Cloth; Specification QMC 6‐31E, 27 September 1933). These items were typically worn with khaki cotton breeches and spiral leggings or tall laced boots. Headgear consisted of an olive‐drab wool or khaki cotton service cap, or the olive‐drab service hat (campaign hat). On 19 April 1938, an 8.2‐ounce khaki twill shirt was approved to be the new outer garment for the khaki uniform replacing the combination service coat and oxford cloth shirt. It would be around another year before stocks of the khaki coat and oxford cloth shirt were sufficiently drawn down so that large scale procurement of the new shirt could begin. Specifications were set for both wool and cotton trousers in 1937 initiating a gradual changeover from breeches to trousers that started with Air Corps personnel. It was on 1 February 1939 that trousers were designated a standard article of uniform for all Army personnel and mass procurement from the garment industry began.

A new design for the khaki cotton shirt emerged in the fall of 1941. This was the result of the Panama Command requesting an open collar shirt for field wear in tropical conditions. Experimenting was done in the summer and fall of 1941 with both long and short‐sleeve sport shirts and knee‐length trousers. Several variations of shirts and trousers were developed and sent to different commands for testing and evaluation. The short‐sleeve shirt was ultimately rejected on grounds that it did not offer enough protection against mosquitos and brush. The knee‐length shorts were abandoned for the same reasons, although testing continued for a longer period of time due to interest by the Armored Command for possible use in desert conditions. A long‐sleeve convertible collar khaki cotton shirt, however, was approved for tropical use on 26 September 1941. This shirt was equipped with a sports collar, otherwise known as a convertible collar. This type of collar was desirable for wear in tropical conditions because it could be worn open in the field, or with a necktie when required. Work continued on the shirt collar and an improved version was approved for wear by all troops on 27 November 1941. The design of the long‐sleeve, convertible collar khaki cotton shirt proved successful and by the spring of 1942 became the standard model shirt in both wool and cotton.

By the summer of 1942, it was realized that a new combat uniform would be needed for upcoming offensive operations in the jungles of New Guinea and the Solomon Islands. It was decided against using the khaki cotton uniform for this role because its light color stood out against the dark green vegetation of the jungle, and it was felt that the fabric lacked adequate durability for the rugged jungle environment encountered in the South Pacific. Because there was neither time nor resources to develop an optimal fabric for jungle operations, it was decided to use herringbone twill for this purpose. Though a printed camouflage one‐piece jungle uniform made in herringbone twill had been developed and approved by late in the summer of 1942, this outfit proved to be too hot and cumbersome for its intended purpose. These circumstances led to the standard two‐piece herringbone twill uniform being officially adopted as a hot and tropical weather combat outfit. No further consideration was given to the khaki uniform as a combat outfit and going forward it was gradually withdrawn as a field uniform. Though khaki clothing served throughout the war as a summer service uniform, by late 1944 it was limited exclusively to this role.

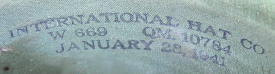

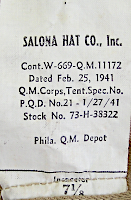

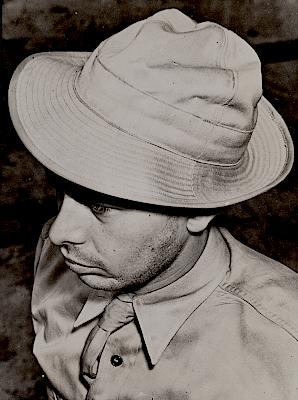

Headgear

In 1941, several different types of headgear were worn with the khaki uniform. These included a field cap (garrison cap), cotton field hat, cloth covered fiber helmet, and the M‐1917‐A1 steel helmet. The khaki field cap, cotton field hat, and fiber helmet were all options approved in late 1940 to replace both the olive‐drab and khaki service caps, as well as the olive‐drab service hat (campaign hat), all of which had been traditionally worn with the khaki uniform. The service cap and campaign hat were marked for elimination due to their cost, use of strategic materials, and the difficulty involved in storing and maintaining them. Though eliminated as a standard issue item in 1940, the enlisted man's service cap remained popular, and both olive‐drab wool and khaki cotton types were readily available for purchase at retail outlets and post exchanges throughout the WW2 period. The Quartermaster Corps stopped procuring khaki cotton service caps in the mid‐1930s after which the olive‐drab type was often worn with the summer uniform, though sometimes with a khaki cover fitted over the top. Service caps made through 1940 were constructed using a traditional wicker frame and had a leather visor and chinstrap, while those made during the war years used an inexpensive fabric frame made of coated buckram, and often had a simulated leather visor and chinstrap. Caps offered at retail outlets sported various visor and chinstrap finishes. Colors ranged from the approved russet shade 90 to cordovan to black and were occasionally made in patent leather.

The cotton field hat (specification PQD 21, 27 January 1941) was introduced as a stopgap replacement for the olive‐drab felt campaign hat, which had been a long‐standing staple worn in the field. With war approaching, the traditional campaign hat was considered too expensive to maintain (it needed periodic re‐blocking to maintain its Montana Peak), required excessive storage space, and was regarded as incompatible with the increasing number of mechanized forces utilizing trucks, armored vehicles, and aircraft. The cotton field hat was made using the same 8.2‐ounce khaki shade 1 cotton twill as the summer shirt and trousers, had a four‐gore crown with a vent hole on each segment, and a full brim for sun and rain protection. Around this same time, a cloth covered fiber helmet was approved for tropical use that offered protection against the sun and brush. This item was made of pressed fiber and was covered with a lightweight khaki twill fabric. It had an adjustable headband, leather chinstrap, and generous brim. Neither the cotton field hat nor fiber helmet were procured for very long. Both items were ultimately supplanted by the two‐piece M‐1 steel helmet and liner assembly adopted in June 1941. The new, pot‐haped M‐1 helmet was developed to provide extended protection to the sides of the head and replaced the saucer shaped M‐1917‐A1 helmet used since the mid‐1930s. The M‐1's fiber liner, and later plastic liner, could be worn separately and was prescribed for light field use with the steel shell being added for combat situations. The adoption of the M‐1's liner as an independent piece of headgear allowed the elimination of both the cotton field hat and fiber sun helmet. Though short‐lived, the cotton field hat was well liked by troops for its sun and rain protection and the fact it could be folded and stored easily. As a result, a herringbone twill version of the hat was procured from June 1941 to May 1942 for wear with the new two‐piece herringbone twill uniform approved in 1941.

Both olive‐drab and khaki cotton garrison caps went through a number of changes leading up to the US entry into WW2. The garrison cap, known as an overseas cap in WWI, and simply as a field cap in the pre‐WW2 years, was modernized and played a role in the replacement of both the olive‐drab service cap and olive‐drab service hat (campaign hat). In 1938, the field cap (specification QMC 8‐114, 25 July 1938) featured a bellows crown, sharp peaks, and a turned‐up curtain crossing the front. During 1939, the field cap was made a standard article of the uniform for all troops to wear. The olive‐drab field cap was reworked again in 1940 and given rounded peaks (specification dated 11 October 1940). On 23 December 1940, approval was given for an 8.2‐ounce khaki cotton field cap (specification PQD 13, 10 January 1941) of a design similar to the olive‐drab cap. The khaki cap was to be trimmed with branch of service colors and issued to troops stationed in the United States as well as overseas. Shortly thereafter, in order to facilitate mass production, a single pattern was developed to produce both the olive‐drab and cotton field caps. The new design had a reduced bellows in the crown and both types of field caps were unified under a common specification (Caps, Field, OD, Type I & Caps, Field, Khaki, Type II; specification QMC 8‐114A, 19 February 1941). By June 1942, new headgear had been developed specifically for field use and as a result the field cap's nomenclature was officially changed to Caps, Garrison to accurately reflect its new status. The inclusion of branch of service braid on the garrison cap carried on the custom and served the same functional purpose as the cord and acorns worn on the campaign hat.

Shirts

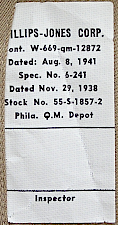

Approved as a standard article of uniform on 19 April 1938, the khaki cotton shirt was to supersede the khaki cotton service coat and oxford cloth shirt combination used heretofore. The new shirt (specification QMC 6‐241, 29 November 1938) was made with 8.2‐ounce khaki shade 1 cotton twill and featured a coat style front with button placket, standing and falling collar, mitered pockets, and shirt‐style cuffs. There were seven front buttons and one button for each pocket and cuff. After stocks of the khaki coat and oxford‐cloth shirt were sufficiently reduced, large‐scale procurement of the shirt commenced in December 1940 and lasted until approximately October 1941.

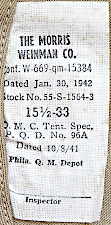

A long sleeve convertible collar 8.2‐ounce khaki cotton shirt was approved for tropical use on 26 September 1941. This shirt featured a sports style collar that could be worn open in hot weather or, when required, buttoned with a necktie. Much experimenting was done to develop a shirt that presented an acceptable military appearance with the collar either opened or closed. Successful implementation of the convertible collar involved the elimination of the front button placket, increasing the distance between the collar button and second button, and remaking the collar into a falling type. The resulting sports style shirt was quite different from the previous dress shirt design, being instantly recognizable by its lack of a front button placket. With the collar design worked out, on 27 November 1941, the long sleeve convertible collar khaki cotton shirt (specification PQD 96A, 8 October 1941) was approved for use by all troops supplanting the dress shirt type. Large scale procurement of the 8.2‐ounce convertible collar shirt lasted from approximately December 1941 through April 1942.

Early in the summer of 1942, a reduced weight fabric was approved for the convertible collar khaki cotton shirt (specification PQD 96C, 23 June 1942). To conserve material and allow clothing production requirements to be met, a 6‐ounce cotton twill fabric was substituted for the 8.2‐ounce fabric then in use. In the fall of 1942, production began on a special variant of the 6‐ounce shirt having gas protective features. The nomenclature was then updated to read: Shirts, Cotton, Khaki, Convertible Collar, 6‐oz., Special. Modifications to the shirt included a flap of material that buttoned behind the front opening, redesigned cuffs that included an inside gusset, and two buttons behind the collar for attaching a gas protective hood. The intention was that, when needed, this shirt could be impregnated with a chemical agent making it resistant to blister gases. Initially, khaki shirt production included both regular and special variations with the special type meant for overseas use. Dual production was the case until the spring of 1943 when all 6‐ounce cotton shirts were made with special features (Shirt, Cotton, Khaki, Special; specification PQD 96D, 21 April 1943).

The final variant of the WW2 khaki cotton shirt was approved in the fall of 1944 (Shirt, Cotton, Khaki; specification PQD 475, 6 November 1944). This shirt had its special gas protective features removed reflecting the khaki cotton uniform's reclassification as a garrison outfit. Initially the shirt was made in 6‐ounce twill fabric and had simplified lapped cuffs. Later, on 24 March 1945, authorization was given to reduce the fabric weight further to 5‐ounces. In the post-war era, the khaki cotton shirt (specification USA 6‐241A, 17 September 1947) would return to many of its pre‐war design features, gain some new ones, and have much more in common with the original 1938 specification.

Necktie

In 1939, a necktie made from 8.2‐ounce khaki cotton fabric was approved for wear with the khaki shirt (Neckties, Cotton, Khaki, Washable; specification QMC 6‐282, 22 August 1939). It was desired to have a washable necktie requiring less care in hot and tropical environments in lieu of the black silk necktie then in use. The cotton necktie was 43‐inches long, reversible, unlined, and had fully stitched triangular tips. In 1940, the black silk necktie was replaced by a wool version (Necktie, Black, Wool, M‐1940; specification QMC 8‐119, 31 January 1941). The new black wool necktie was a four in hand pattern that was folded into triangular tips and was 45‐inches long. Soon wool was designated a critical material resulting in the development of a mohair and cotton blend necktie that was approved on 24 February 1942. At first, the mohair blend necktie was made in olive‐drab shade No. 3 but was changed rather quickly to khaki shade No. 5. The khaki shade 5 mohair and cotton blend necktie supplanted all previous models and became standard issue for the remainder of the war years.

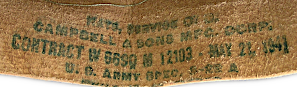

Trousers

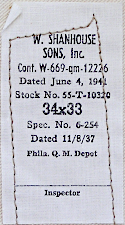

Like the shirt, several variations of khaki cotton trousers were produced during the WW2 period. Changes were implemented for multiple reasons including improved fit, simplified patterns to boost production, implementation of gas protective features, and resource conservation requirements. There were two lineages of khaki cotton trousers that were produced concurrently throughout the WW2 period. The first bore the specification QMC 6‐254 along with a series of derivatives that used the specification PQD 339. Second, was a series of khaki trousers bearing the specification PQD 19.

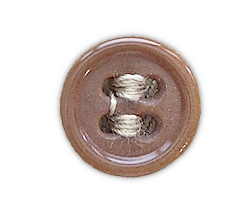

The Army began replacing breeches with trousers in 1937. Khaki cotton trousers (specification QMC 6‐254, 8 November 1937) were full length trousers made in 8.2‐ounce cotton twill dyed in khaki shade No. 1. The trousers had an integral waistband, five internally hung pockets, and seven belt loops. There were two vertical hip pockets with canted openings, a front watch pocket below the right waistband, and two horizontal slit pockets on the seat. The trousers were fashioned with shaping darts located at the waist above the seat pockets. Khaki trousers produced before 1942 had dish shaped zinc buttons stamped with "U.S. Army" around the perimeter. This style of button was a feature shared with two‐piece blue denim work uniforms and khaki cotton breeches of the period. Beginning in 1942, buttons were changed to a flat plastic type. There was one 27‐ligne waistband button and four 22‐ligne fly buttons. Though many changes in detail would be forthcoming, the basic description and general appearance of the khaki trousers remained the same throughout the war years.

Specification 6‐254 was amended twice in 1942 to incorporate changes into the khaki trouser design. In early March 1942, the Quartermaster increased the rise (the distance between the bottom of the crotch to the top of the waistband) and added an additional two inches to the seat in response to complaints of trousers not fitting properly. In the fall of 1942, a flap was added behind the front fly as a means of protection against blistering agents reaching the skin. To denote this change, the nomenclature was updated to read Trousers, Cotton, Khaki, Special with the word special meaning the gas flap was present. The protective flap remained a part of the trouser design through the end of specification 6‐254 procurement in November 1942.

In 1943, a new specification was issued for a modified version of the special khaki cotton trousers (specification PQD 339, 12 February 1943) in lieu of the 6‐254 specification. These trousers were made with simplified single welt watch and rear pocket openings. This type of pocket opening was easier to manufacture than the double welt pattern previously used. Simplified pockets first appeared on the specification PQD 19 series of khaki cotton trousers to be discussed below. In addition to the modified pockets, in March 1943, the Quartermaster again authorized an increase in the dimensions of the seat and rise of enlisted men's trousers. By this time, the seat of enlisted men's trousers had become noticeably baggy. The unifying feature of the 6‐254 and 339 specifications was the use of double stitched flat felled seams that served as the basis for construction. This type of seam utilized a double row of stitching that is plainly visible on the outside of the trousers, most notably running down the outer leg. The gas flap was removed for the final iteration of these trousers (specification PQD 339A, 20 January 1945) reflecting the reclassification of the khaki uniform for garrison use.

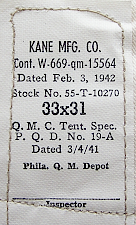

By early 1941, with the Army rapidly expanding, the Quartermaster took steps to ensure clothing production would meet minimum basic requirements. One such strategy was to offer alternative construction methods thereby enabling more garment manufacturers to participate in the production of clothing for the Army. With millions of units needed, a simplified pattern was developed for cotton trousers (specification PQD 19A, 4 March 1941). The most important change involved substituting single stitch plain seams for the double stitch flat felled seams previously specified. This change allowed manufacturers of dress slacks to make cotton trousers that were normally made by manufacturers of workwear. Pockets were also simplified by changing the method in which the rear and watch pocket openings were made. This involved using a single welt design instead of the more complex double welt pockets then in use. These changes resulted in an economized version of the khaki cotton trousers that could be produced faster and by a greater number of manufacturers. The key identifying feature of specification 19A trousers are the single stitch plain seams which were sewn from the inside and are visibly different from the flat felled seams that are double stitched from the outside.

Specification PQD 19 trousers went through the same modifications as did the QMC 6‐254 and PQD 339 specifications. Like its peers, in March 1942, the rise was made higher and the seat wider. A gas flap was added across the front fly in the next iteration (specification PQD 19B, 2 February 1943) with the nomenclature being changed to read Trousers, Cotton, Khaki, Special to indicate the modification. In addition to the gas flap, in March 1943, the seat was again made wider. But, by early 1945, advances in clothing developed specifically for combat effectively eliminated the khaki cotton uniform from such use. Thus, the final wartime variant of khaki trousers (specification PQD 19C, 22 January 1945) had the gas flap removed with the nomenclature being reverted to Trousers, Cotton, Khaki.

Undergarments, Overgarments & Other Items

Summer weight undergarments were worn with the khaki cotton uniform. These consisted of short white cotton drawers (specification QMC 6‐188B, 6 October 1936) and a white sleeveless undershirt (specification QMC 6‐233A, 1 September 1936). The shorts featured a plain weave, full back panel, side‐adjusting ties, and a three‐button front opening. The summer undershirt was cut in the athletic style and knitted in ribbed and flat‐stitch white cotton. It featured bound armholes, a collarette neck, commercial grade 1½‐inch shoulders, and a ¾‐inch bottom hem. In the pre‐war years cotton undergarments were made in both white and olive‐drab colors, but by 1943 the color had been changed to olive‐drab for the remainder of the war.

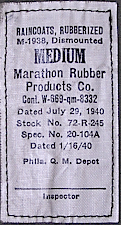

Exterior garments were sometimes worn with the khaki cotton uniform. Two garments in particular were the field jacket and raincoat, both of which were part of the enlisted man's individual clothing allowance. When in the field, the olive‐drab field jacket was de rigueur except in tropical climates where it was not issued. Depending on the discretion of the commanding officer, the field jacket could also be worn in a more casual manner when a windbreaker or a little extra warmth was required. The raincoat was also an essential part of the enlisted man's field uniform and was carried in the pack when not in use. Raincoats were a rapidly changing item during the WW2 years. From 1940 to 1942, a rubberized type was issued (Raincoat, Rubberized, Dismounted, M‐1938; specification QMC 20‐104, 7 January 1939). Several derivatives of the M‐1938 model were produced until mid‐1942 when a synthetic resin coated raincoat became standard issue. The M‐1938 types were notable for their standing and rolling collar, outside bellows pockets, throat closure latch, vented back, and tightening straps on each sleeve. Each successive model of M‐1938 raincoat became increasingly economical in features until the emergence of the resin coated types which had a substantially different appearance. Late in the war, synthetic rubber coated models began to replace the resin coated types.

The standard Army belt worn with enlisted men's trousers during the WW2 period was the M-1937 waist web belt (specification QMC 6‐105, 25 March 1938). It consisted of a 1¼‐inch‐wide woven cotton belt in olive‐drab with a friction frame buckle clamped to one end and a small metal clip at the other end to prevent the fabric from unraveling. Initially, buckles and hardware were made of blackened brass, but beginning in the fall of 1941, buckles and clips made with oxidized steel alloy were allowed (specification JQD 19, 19 September 1941) in order to conserve brass for more critical uses. In addition to regulation belts, khaki shade web belts were available for purchase at post exchanges and retail outlets. These belts often had solid brass buckles or gold washed metal alloy buckles instead of frame buckles.

Footwear

When trousers became standard issue throughout the Army in 1939, canvas leggings (specification QMC 6‐288, 8 August 1940) that were made of No. 6 canvas duck and 12 ¾‐inches high were approved for field wear to protect the shin area and keep debris out of the trousers and service shoes. Leggings were laced around the outside of the lower leg using a series of hooks and eyelets. A strap and buckle fastened around the shoe shank to secure the bottom. Trousers were tucked inside the top of the leggings. This setup replaced the breeches, spiral leggings, and service shoe combination previously used and the enlisted men's laced leather boots that extended over the calves. Early leggings were made of khaki shade canvas and had polished brass hardware. However, during 1940‐41, olive‐drab shade 3 canvas and blackened brass hardware was being phased in. In 1942, to conserve critical materials, the metal components were changed to oxidized steel and zinc (Leggings, Canvas, Dismounted, M‐1938; specification JQD 212, 12 October 1942).

Service shoes were the most common type of footwear worn with the khaki uniform during the WW2 era. These shoes were a high‐top, blucher pattern, unlined, with a toe cap. The uppers were cowhide and finished in russet shade 90. Prior to 1940, service shoes had leather outsoles and fully stacked leather heels. In 1940, a rubber heel was added. In 1941, the service shoe was modified slightly (specification QMC 9‐6F, 19 November 1941) and eventually four different types were based on this design. The Type I shoe had a leather outsole and rubber heel; the Type II shoe had a composition leather and rubber half-sole and rubber heel; the Type III shoe was made with reverse leather uppers and a full composition sole; and lastly there was a special requisition hobnailed variant with fully stacked leather soles and heels. Service shoes were procured approximately to the summer of 1943 when composition sole combat service boots began replacing them.

A light garrison shoe (Shoes, Garrison; specification QMC 9‐35A, October 1932) was also made for office personnel and other light duty use. These shoes looked similar to the standard issue service shoe but were made with calfskin uppers and had a cotton lining. The outsoles were full leather, and the heels had a rubber tap. Procurement of garrison shoes was stopped by 1940 to concentrate on making service shoes in the quantity needed for the expanding Army. In 1941, a less expensive low quarter shoe was introduced (Shoes, Low Quarter, Tan; specification BQD 55, 1941) that superseded the garrison shoe for light duty use. Procurement, however, remained concentrated on more important service shoes and later combat boots throughout the WW2 period. As a result, low quarter shoes were produced in limited quantities and their issue was restricted to specially designated personnel such as those assigned to the Medical Corps or Officer Candidates.

In 1938, matching tan cotton socks (Socks, Cotton, Tan; federal specification JJ‐S‐566A, 26 August 1938) were authorized for wear with the khaki cotton uniform and were procured throughout the war years. Although these socks were worn with all types of shoes, they were lightweight and not considered appropriate for prolonged field wear or marching. The tan cotton sock was a seamless design with a 5 ½ to 6‐inch Ribbed top and a reinforced heel and toe.

White light or heavy wool socks (Socks, Wool and Cotton Mixture; specification JJ‐S‐581A, dated 22 August 1938) were available for field wear with service shoes and leggings. By 1943 most wool socks along with undergarments of all types were being made in olive‐drab instead of white. In August 1942, an improved olive‐drab wool sock with a cushion sole (Socks, Wool, Cushion Sole; specification PQD 236) was developed. Once established, the cushion sole sock became the prescribed sock to be worn with service shoes and combat boots.

Conclusion

During WW2, the khaki cotton uniform was an essential part of the enlisted man's wardrobe. It was part of his individual clothing allowance unless assigned to arctic or sub-arctic stations. Early in the war, two sets of khaki uniforms were typically issued at induction and maintained throughout the enlisted man's time in service. The uniform was habitually worn in summer conditions and year‐round in tropical garrisons, such as the Panama Canal Zone, the Philippines, the Caribbean, and Hawaii. Unless assigned to a tropical location, the khaki uniform was not taken along when embarking for overseas stations. For the millions of men who served in the Army during WW2, this meant that enormous numbers of khaki clothing had to be procured. Because of this, numerous changes were made to the uniform in order to facilitate production and meet functional needs. These changes, while of interest to the uniform historian, are more or less irrelevant to most military collectors whose interest typically lies with specific units, battles, or individuals. Thus, the minutia surrounding the uniform generates little interest within the general collecting public. More so, the khaki uniform is primarily remembered as a garrison uniform and for the most part lacks the elevated historical status generally assigned to combat uniforms. This is so, even though the khaki uniform was worn as a combat uniform in the early stages of the war in the Philippines and to a limited in extent in the early counter offensives in the South Pacific and North African Theaters. Khaki uniforms were also worn by Army Air Force personnel in the South Pacific and the China, Burma, India theater of operations. Uniforms of Army specification were even procured by the Navy and worn by their aviators and ground personnel in the Pacific. Despite this, interest in the khaki cotton uniform languishes compared to other WW2 era uniforms, especially those recognized as combat outfits. The fact that the khaki uniform wasn't used to any significant degree in the European Theater of Operations, where the majority of current interest exists, contributes to its forgotten status.

After the war ended, the enlisted man's khaki cotton uniform regained some of its pre‐war features and some new ones were added. In 1947, new specifications were assigned to both the shirt (Shirt, Cotton, Khaki, Shade 1, Stand‐up Collar, 8.2‐ounce; specification USA 6‐241A, 17 September 1947) and trousers (Trousers, Cotton, Khaki; specification USA 6‐254A, 4 November 1947). Trousers seams returned to the pre‐war flat felled type, but the wartime instituted simplified rear and watch pocket openings were retained. In reflection of the uniform's garrison status, the trouser seat, which had been repeatedly expanded during the war years, was made closer fitting. The shirt returned to its pre‐war 8.2‐ounce khaki shade 1 fabric, standing and falling collar, and front button placket. Shoulder loops were also added to display combat leader loops, and the shirt was now tapered at the waist for a closer fit. At the same time the shirt and trousers were revised, a light‐weight khaki shade 1 poplin shirt was also added to the wardrobe for wear under the service coat or jacket.

Khaki cotton twill shirts and trousers have been part of the civilian summer work wear market before, during, and after the WW2 era. Returning WW2 veterans quickly recognized the adaptability of khaki trousers to civilian life using them for work and weekend wear. This use helps to explain the relative scarcity of WW2 manufactured khaki trousers that exist today compared to olive‐drab wool trousers. Influenced by their post‐war use, the popularity of khaki trousers soon spread, eventually becoming a favorite on college campuses. By the 1990s, casual wear in most workplaces had become acceptable and khaki trousers enjoyed a surge in popularity as a new alternative to more traditional work slacks. Generically known as "khakis", or by their specific brand names, such as Dockers, these cotton twill trousers were worn to work in offices across America during the 90s decade. Khakis came in many styles, however some manufacturers marketed trousers boasting of their faithfulness to the WW2 design standard. Today, the WW2 khaki cotton uniform lives on through quality reproductions made for the reenacting and living history enthusiast by a host of companies located around the world.

Bibliography

- War Department. Table of Basic Allowances No. 21. Quartermaster Clothing And Individual Equipment. 23 February 1942. Washington, D.C.: Office Of The Quartermaster General, 1942.

- Risch, Erna & Pitkin, Thomas M. Historical Section Office of The Quartermaster General. Clothing the Soldier of World War II. Q.M.C. Historical Studies No. 16, September, 1946. Washington, D.C.: United States Government Printing Office, 1946.

- Brown III, William L. and Bradford, Walter H. Historical Furnishings Report Fort Cronkhite: Barracks (Building 1059) and Mess Hall (Building 1049). National Park Service, U.S. Department of the Interior, Media Service, Harpers Ferry Center, 2005.

- Emerson, Willian K., Lt. Col. U.S. Army. Chevrons Illustrated History and Catalog of U.S. Army Insignia. Smithsonian Institution Press: Washington, D.C., 1983.

- Civilian Production Administration, Industrial Statistics Division. Alphabetical Listing of Major War Supply Contracts. (Culmulative June 1940 Through September 1945), 1946

- Stauffer, Alvin P. United States Army In World War II, The Technical Services, The Quartermaster Corps: Operations In The War Against Japan. Center Of Military History, United States Army, Washington, D.C., 1990.

- Ross, William F. & Romanus, Charles F. United States Army in World War II ‐ The Technical Services ‐ The Quartermaster Corps: Operations In The War Against Germany. Washington, D.C.: Center of Military History, United States Army, 1991.

- Richardson, Eudora Ramsay; Allan, Sherman. Quartermaster Supply in the European Theater of Operations In World War II (Volume III, Outfitting The Soldier). The Quartermaster School, Camp Lee, Virgina, 1948.

- War Department. Army Regulations No. 600‐35. Personnel: Prescribed Service Uniform. 10 November 1941. Washington, D.C.: United States Government Printing Office, 1941.